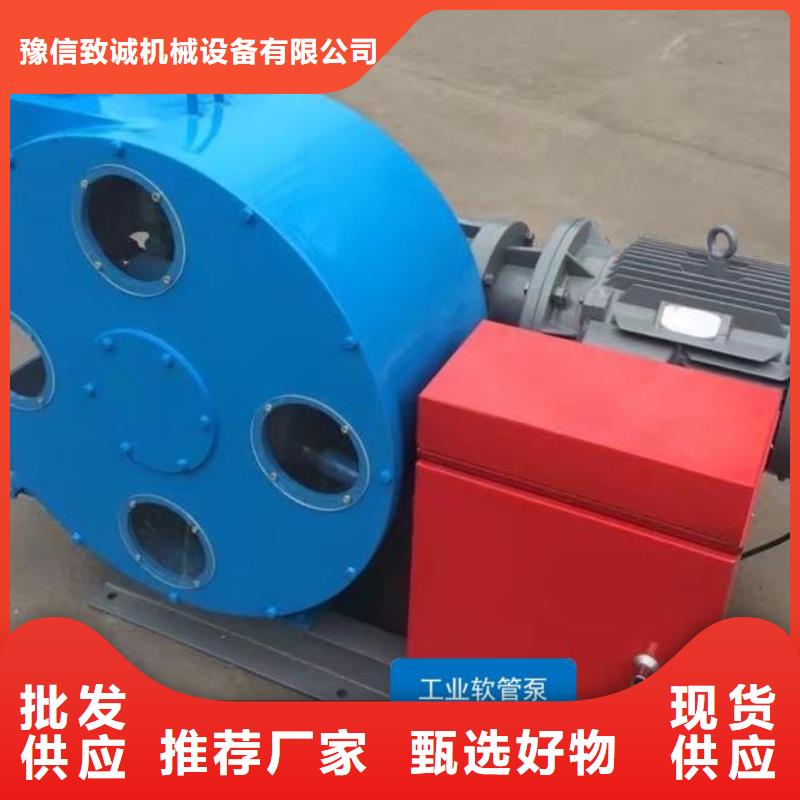

众所周知软管泵在运行时,是通过一根U型附有弹性的橡胶软管来完成输送。今天小编需要强调的是,软管存放时间不宜过长,一般以一年为限。在停工期间,对装有软管的泵,若长期不用,每隔一个月需转动泵一次。以免压辊长时间压在泵管的某一处,减弱管子回弹性,影响其流量的输送。

It is well known that when the hose pump is running, it is conveyed through a U-shaped rubber hose with elasticity. Today the editor needs to emphasize that the storage time of the hose should not be too long, and it is generally limited to one year. During the shutdown period, if the pump is equipped with a hose, if it is not used for a long time, the pump needs to be rotated every other month. So as not to press the roller for a long time at a certain position of the pump tube, it will weaken the resilience of the tube and affect its flow rate.

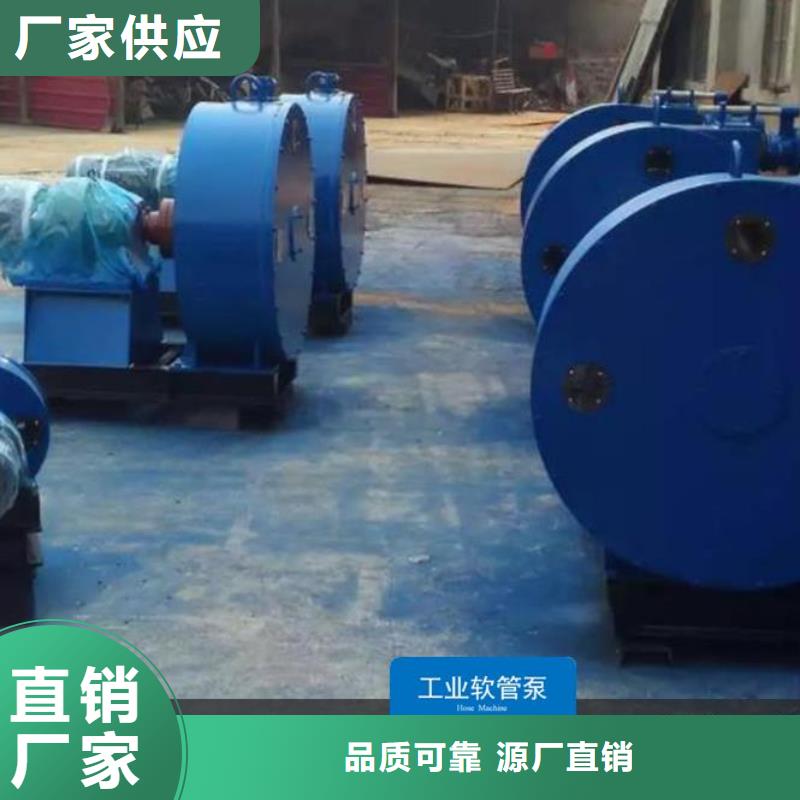

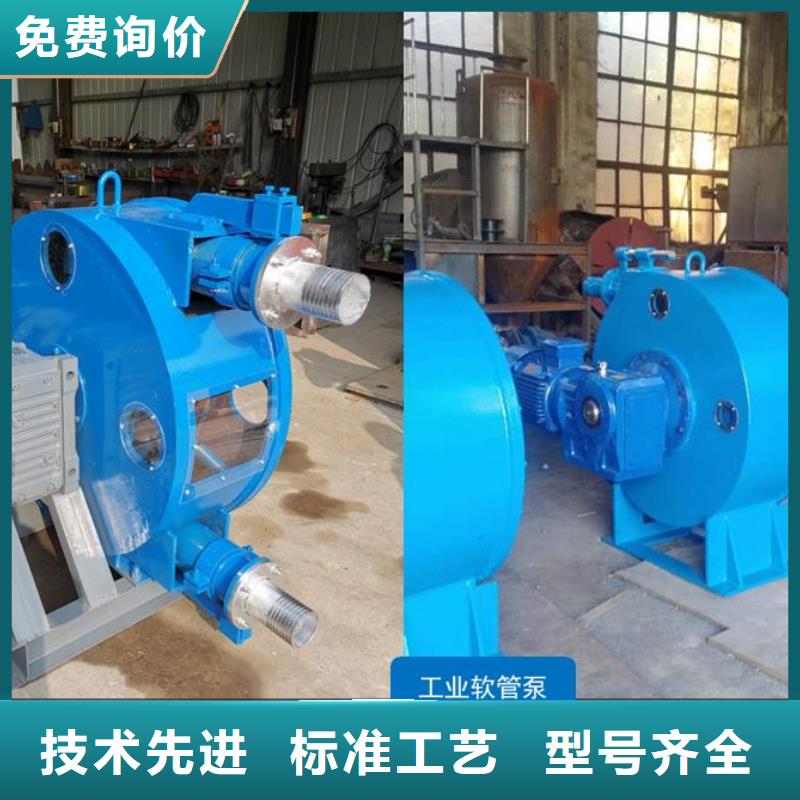

单管软管泵特点:

动力消耗少,可计量输出;易损件少,更换时间短;独特无密封结构,不会产生泄露;自吸能力强,可达8米;可正反向运转,具有自清理能力;压轴采用滚动摩擦,泵腔无需加油;结构简单,操作维修方便;出口压力 可达1.6Mpa;输送高粘度、高固含量、固体颗粒、纤维物质、及其他杂志等液物料,不会产生任何堵塞。

Less power consumption, accurate metering output; less wearing parts, short replacement time; unique non-sealed structure, no leakage; strong self-priming ability, up to 8 meters; can run forward and reverse, with self-cleaning ability; final shaft Rolling friction, no need to refuel the pump cavity; simple structure, convenient operation and maintenance; outlet pressure up to 1.6Mpa; conveying high viscosity, high solid content, solid particles, fibrous material, and other magazines and other liquid materials, without any blockage .

工业软管泵设备特性说明:部分特性说明。

(4)自吸力高。相对于其他形式的容积式泵比较,理论自吸高度可达到9.5m。一般渗滤液都在储液池中,需要高自吸力的泵将渗滤液吸上来,然后输送到过滤器或焚烧炉中。

(5)安装变频电机后,可根据实际需要处理的垃圾渗滤液的多少轻松的调节电机工作频率,可达到流量的线性变化。使得整个垃圾渗滤液回喷系统操作简单,自动化程度高。

(6)泵腔内部便于清洗。当不需要输送时,可打开进出口端的旁通管路可将软管内清洗干净,延长软管的使用寿命。

BW软管泵的基本结构<br />

往复泵由动力段和液力端两大部分组成。<br />

动力端的功能,是将动力机的回转运动转变为活塞(或柱塞)的直线往复运动。它包括传动离合装置、变速减速装置和曲柄连杆。它们的相互位置与安排决定着泵的总体结构型式,决定着泵的驱动方案及结构方案的选择。动力端的主要零部件包括皮带轮,离合器曲轴箱体及其中的传动轴,齿轮副,曲轴,连杆及十字头滑块。<br />!

豫信致诚机械设备有限公司主要致力于甘肃定西及周边地区用户的 甘肃定西水渠机需求服务,我司正一如既往的为众多企业提供定制化服务,且根据客户的不同要求, 甘肃定西水渠机产品已涉及到不同类别、行业。

我厂生产的 甘肃定西水渠机已经成为甘肃定西较具竞争力的厂家之一。公司以市场需求为目标,结合现代技术,自主研发设计通用性强,适用于市场的 甘肃定西水渠机产品。

云 发 布-

云 发 布-