以下是:水平网带输送机订制的产品参数

| 产品参数 |

|---|

| 产品价格 | 1200/米 |

|---|

| 发货期限 | 15 |

|---|

| 供货总量 | 64335 |

|---|

| 运费说明 | 电议 |

|---|

以下是:水平网带输送机订制的图文视频

水平网带输送机订制,浩宇输送机械制造厂专业从事水平网带输送机订制,联系人:许经理,电话:0534-5813888、17853417888,QQ:732358124,发货地:德州经济开发区泰山路南首路西发货到河北省 石家庄市、唐山市、秦皇岛市、邯郸市、邢台市、保定市、张家口市、承德市、沧州市、廊坊市、衡水市,以下是水平网带输送机订制的详细页面。 河北省 河北省,简称“冀”,是中华人民共和国省级行政区,省会石家庄,位于北纬36°05′-42°40′,东经113°27′-119°50′之间,环抱首都北京市,东与天津市毗连并紧傍渤海,东南部、南部衔山东省、河南省,西倚太行山与山西为邻,西北部、北部与内蒙古自治区交界,东北部与辽宁省接壤,总面积18.88万平方千米。河北省下辖11个地级市,共有49个市辖区、21个县级市、91个县、6个自治县。截至2022年末,河北省常住人口为7420万人。

不要犹豫,花一分钟时间观看我们的水平网带输送机订制产品视频吧!您将发现更多令人赞叹的细节和优势,为您的购买决策提供有力参考。

以下是:水平网带输送机订制的图文介绍

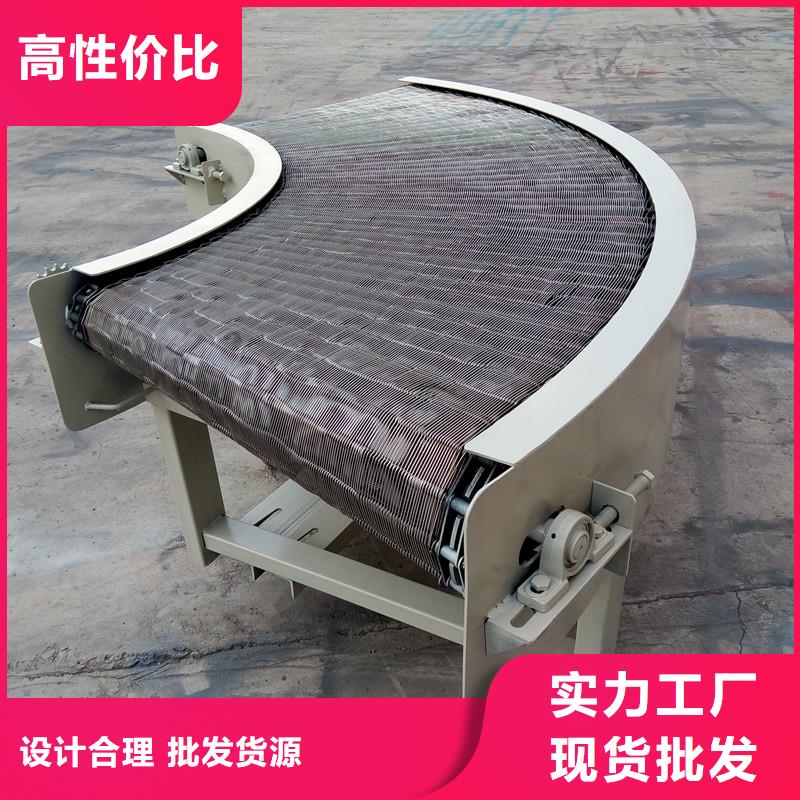

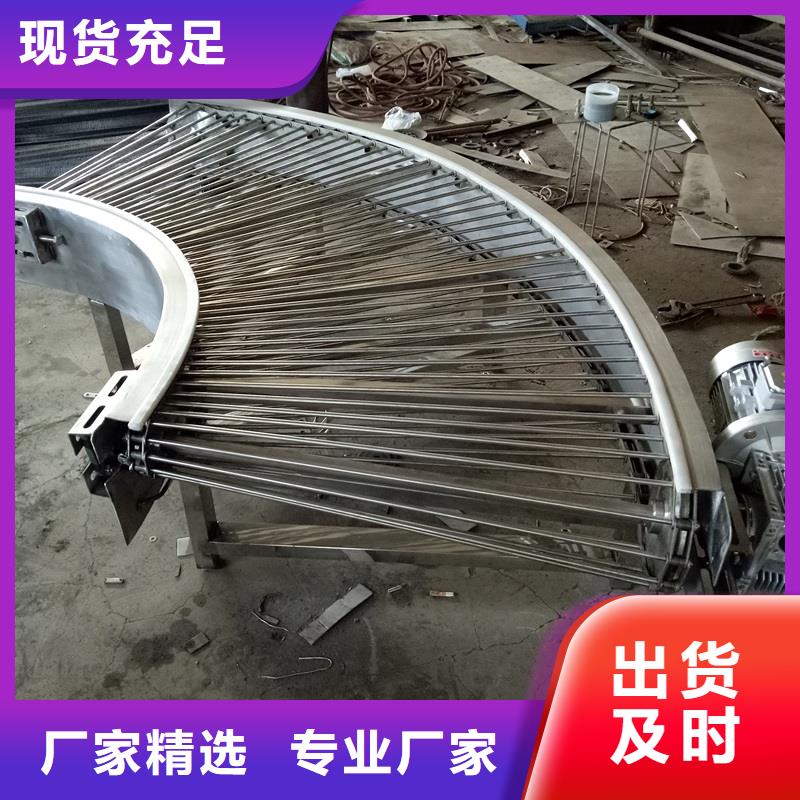

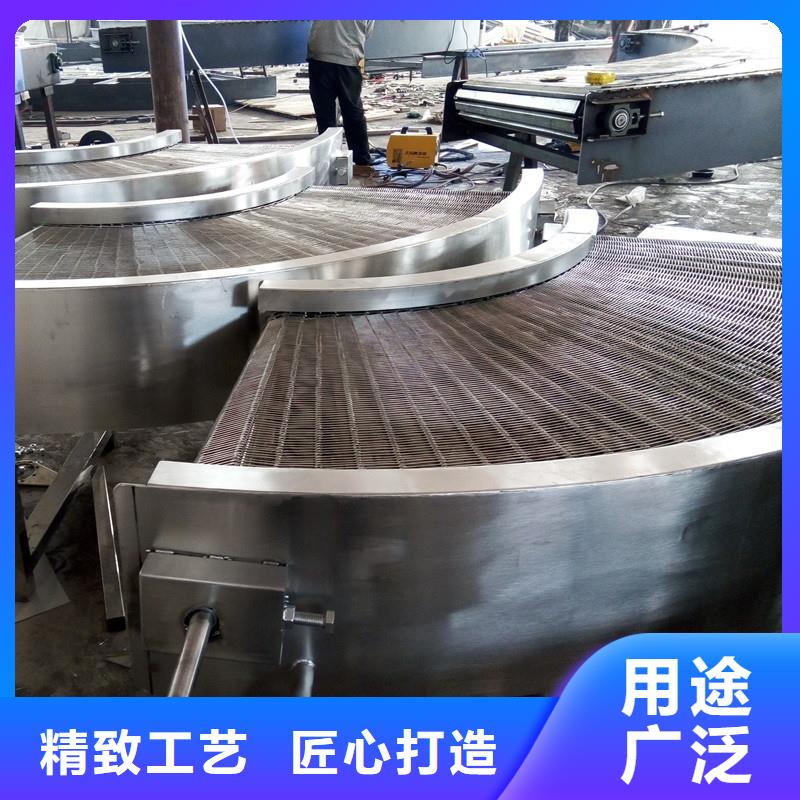

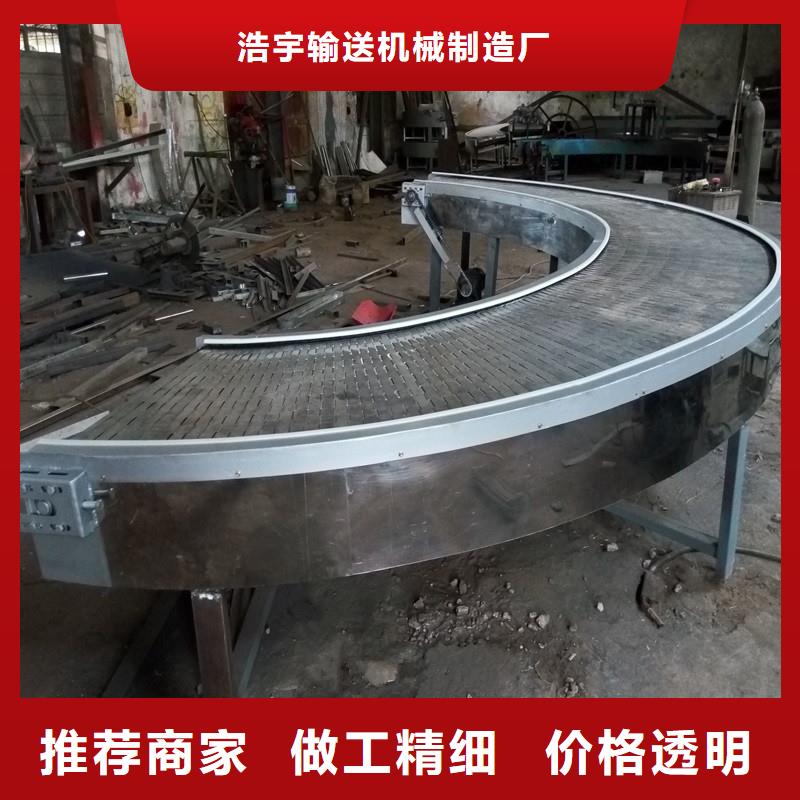

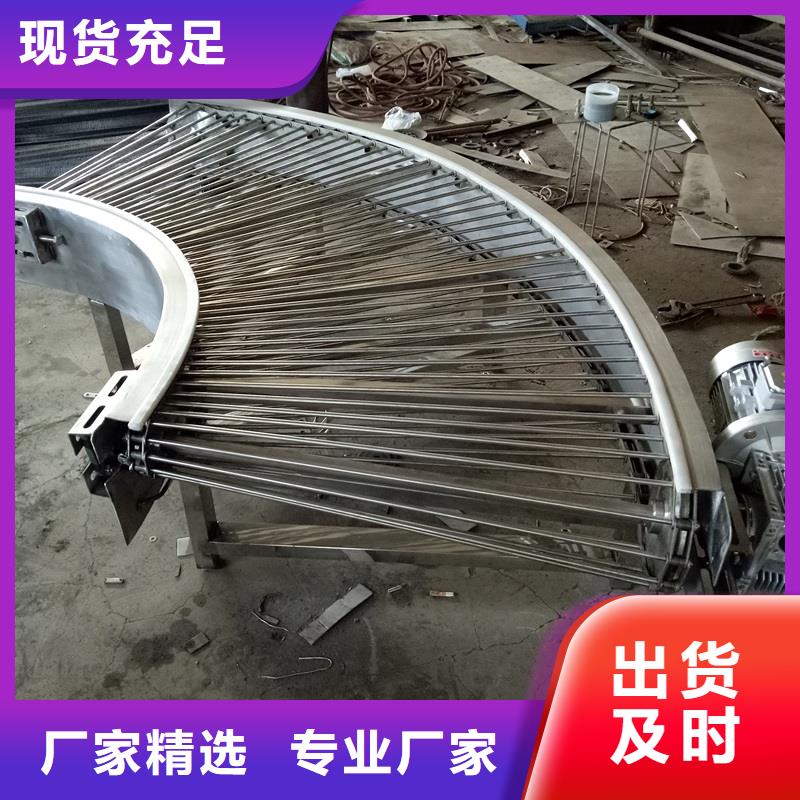

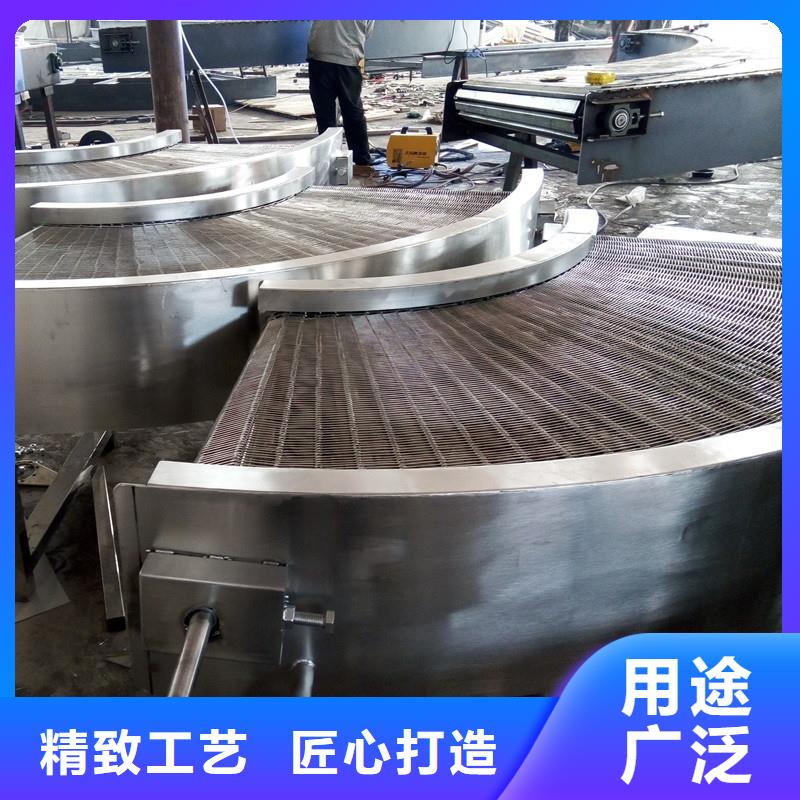

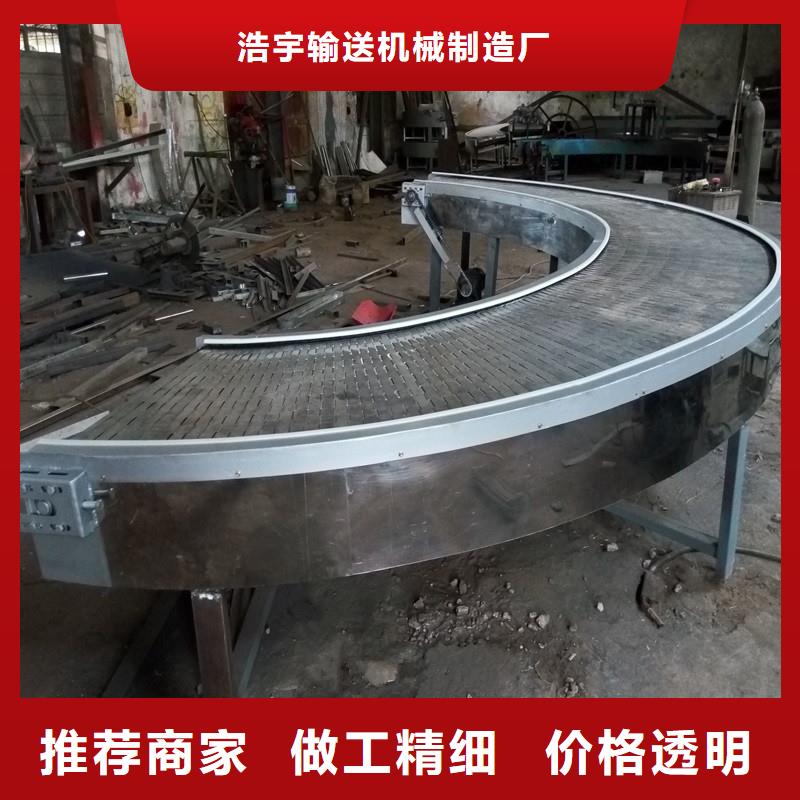

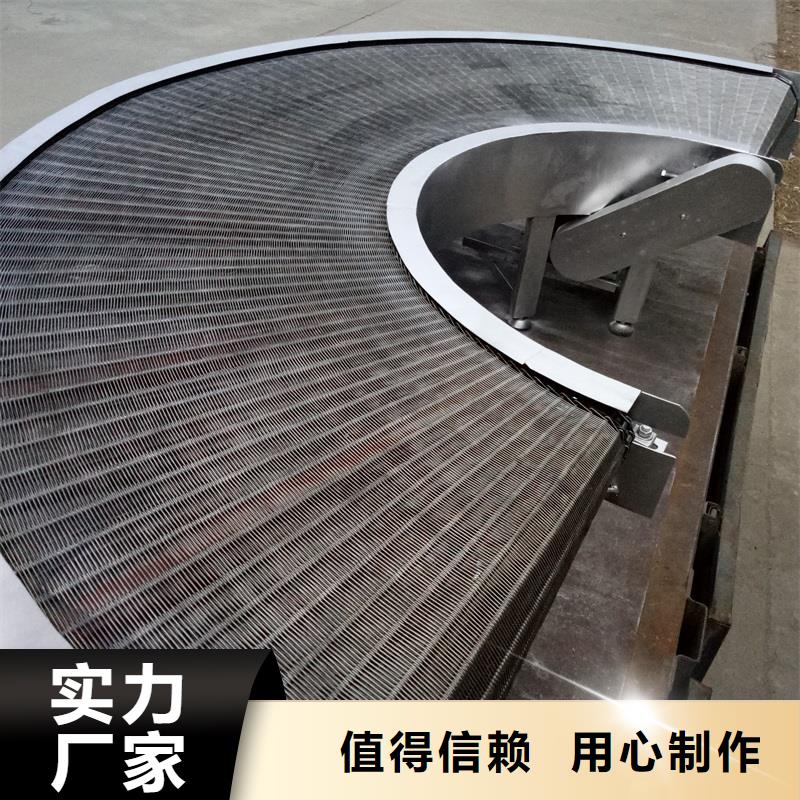

随着当前市场经济的不断发展,浩宇输送机械制造厂所有员工将以以更加完善的【河北转弯机】产品和服务竭诚与国内外客商广泛合作。与时俱进,不断提高【河北转弯机】产品质量,积j i开拓新产品,努力客户满意度。

企业核心理念:靠诚信广交朋友,用真情拓宽事业,为和谐实现双赢。

企业服务理念:打过一次交道,便是永远的朋友。

企业质量理念:用心制造、持续改进、精心服务、用户满意。

企业管理理念:责任有限,责任心无限

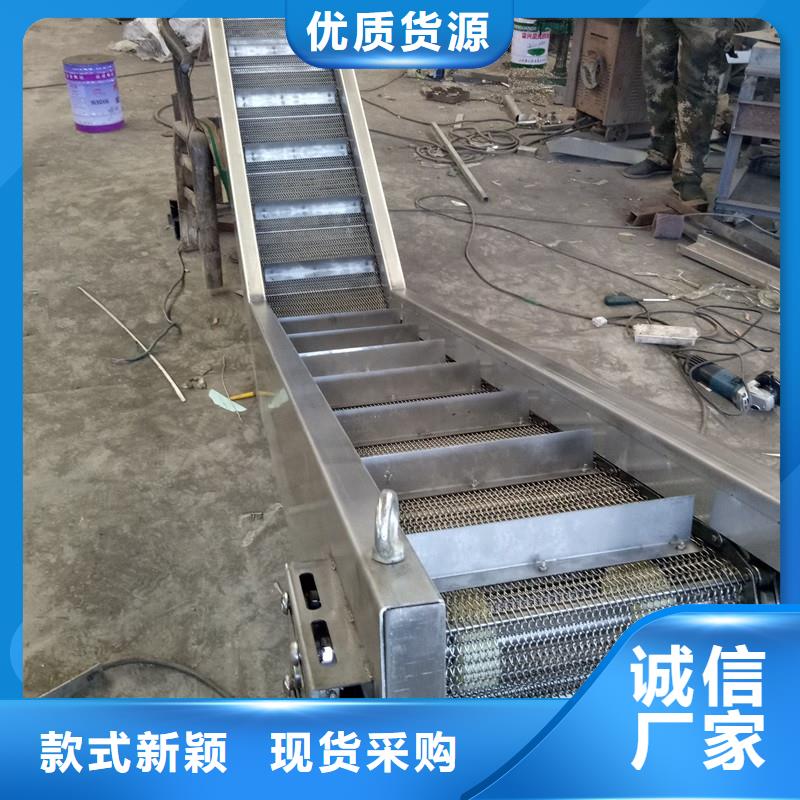

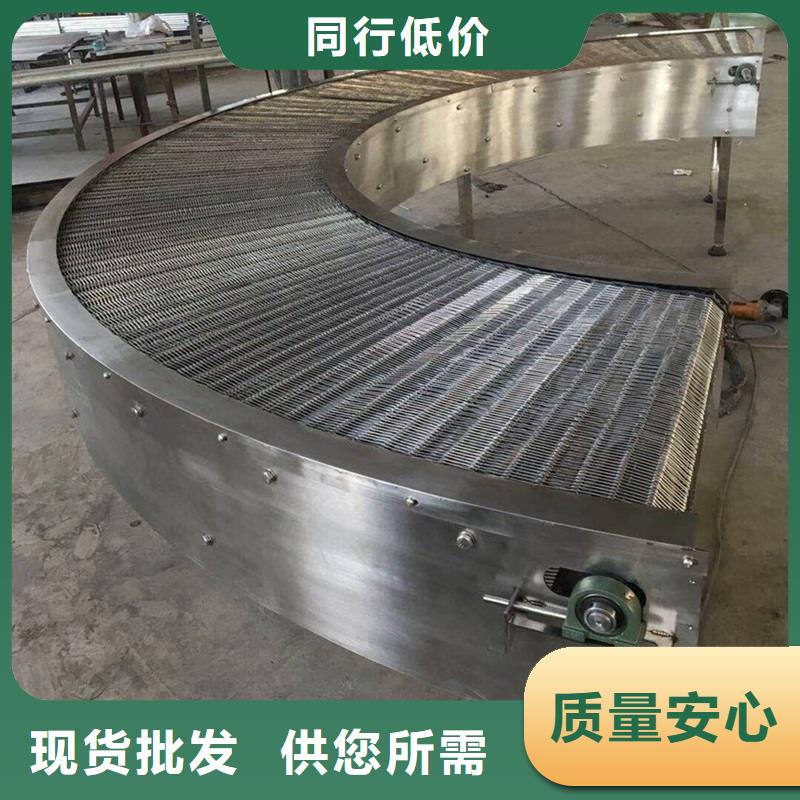

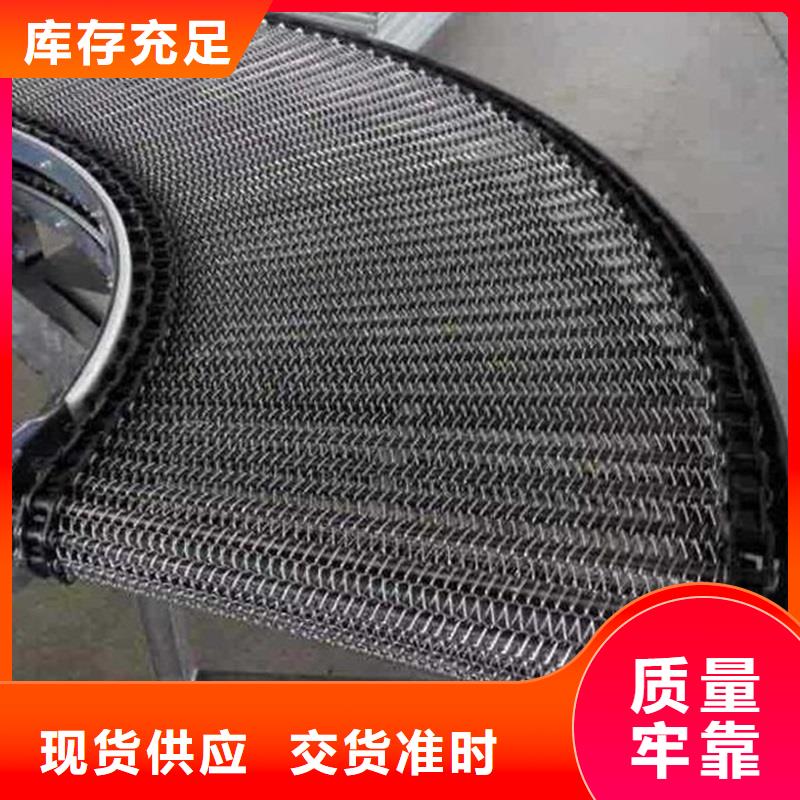

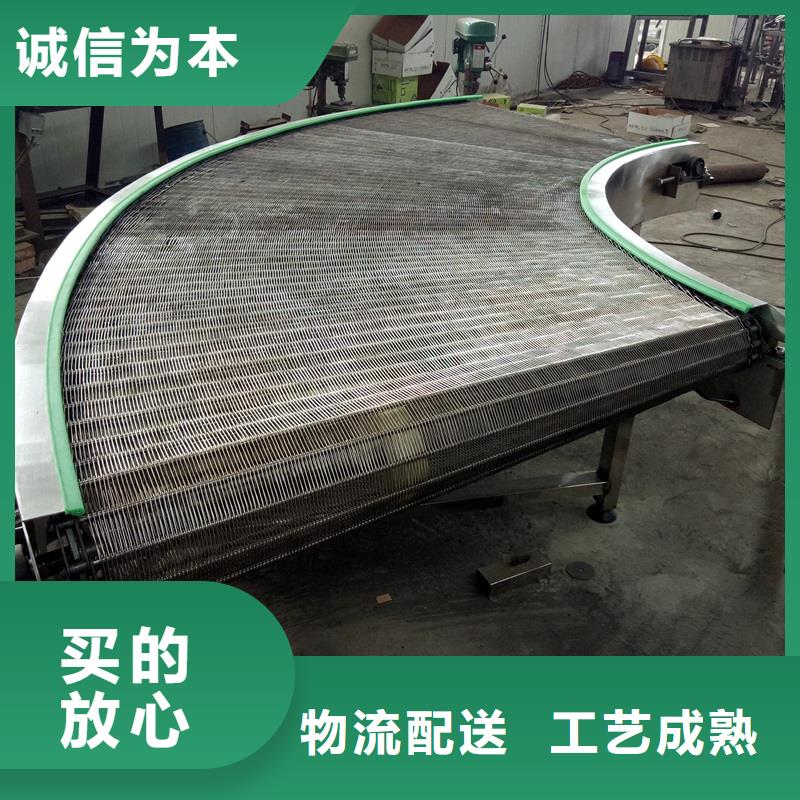

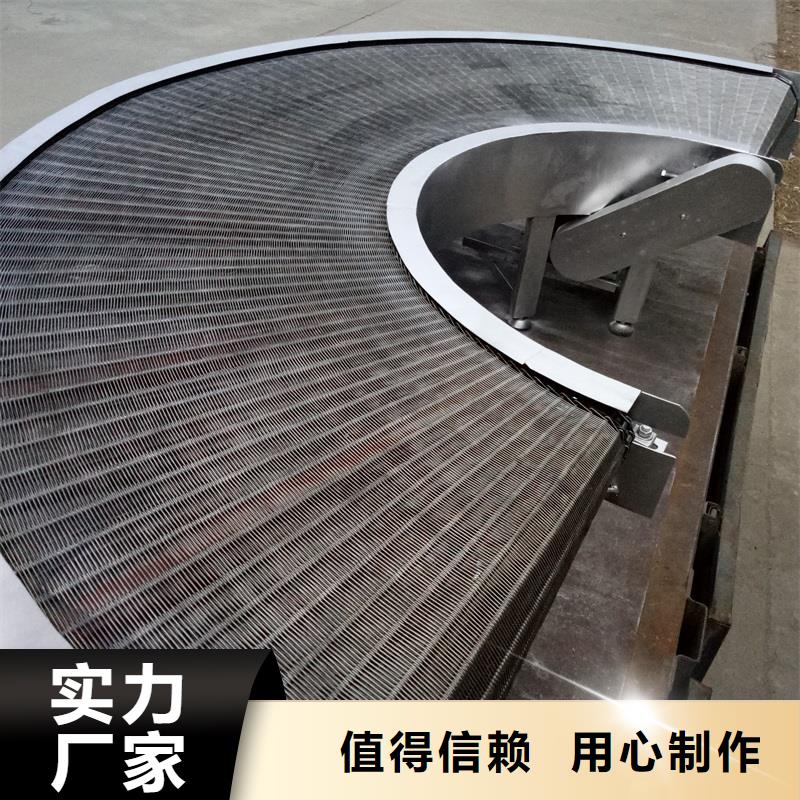

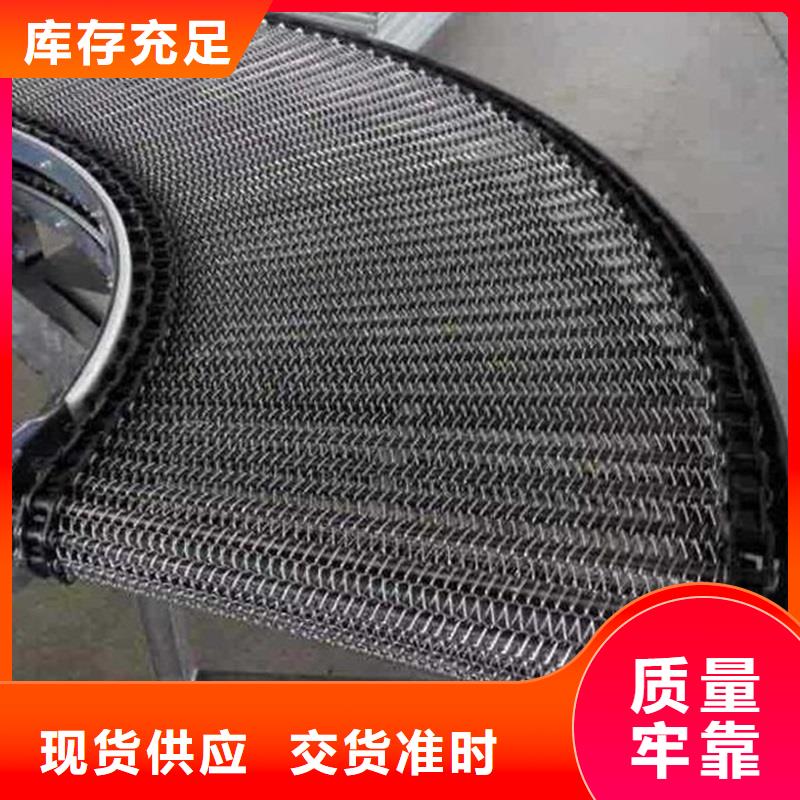

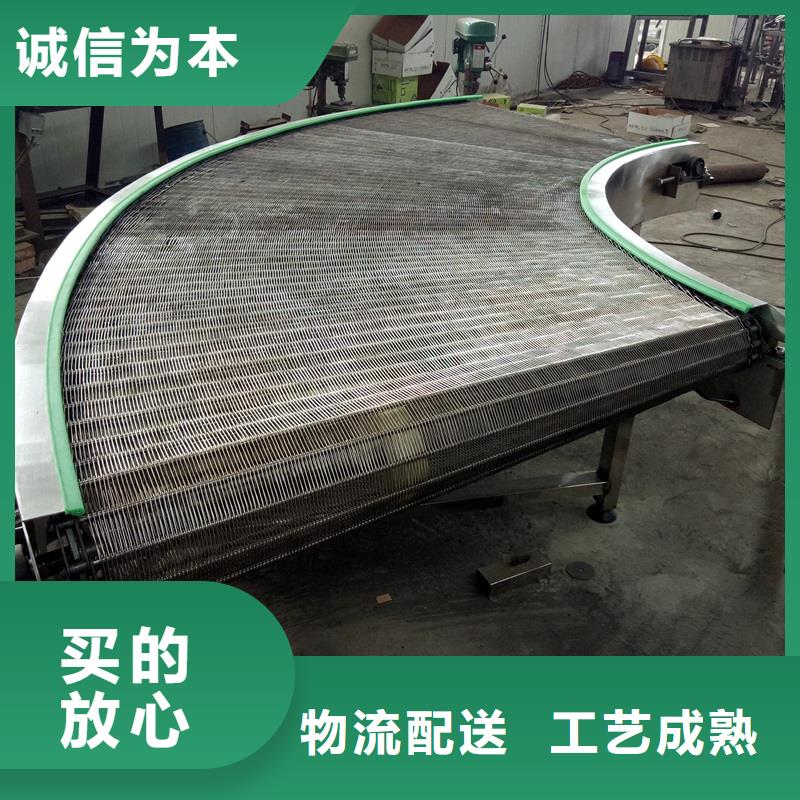

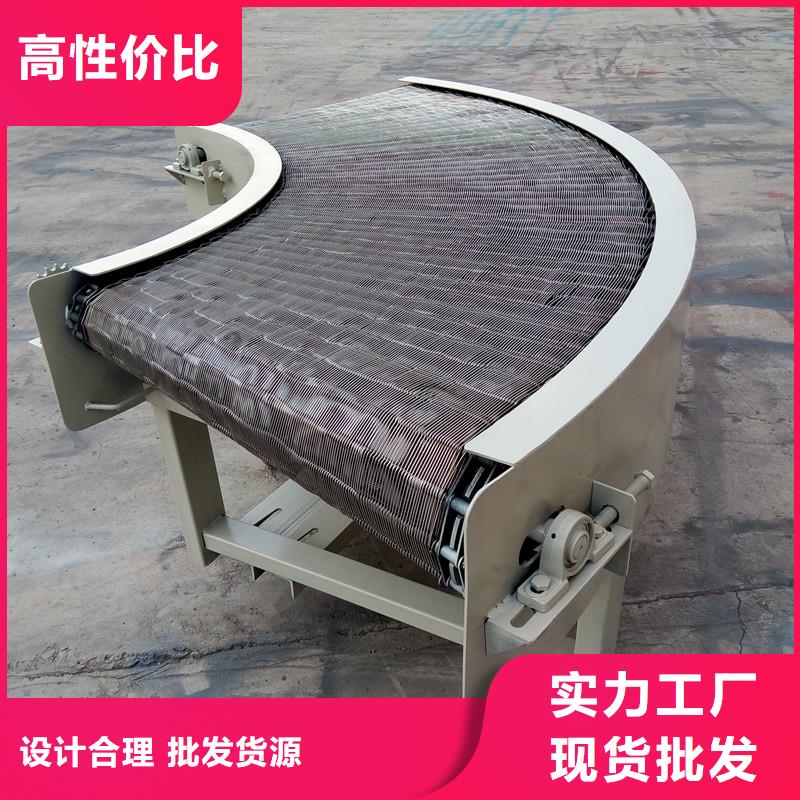

网带输送机网带输送机:模块式网带用延伸在输送带整个宽度上的塑料铰接销,把注塑成型的网带组装成互锁单元。这种方法增加了输送带的强度,并可以组接成任何需要的宽度和长度。挡板和侧板也可以用铰接销互锁,成为输送带整体部件之一。网带输送机结构形式有:水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。插件线输送机插件线输送机采用专用铝合金导轨,靠近操作面一边的导轨固定,另一边可调节移动,保证操作每一次拾取元件距离小,提高生产效率。该设备对于电子基板的流水作业非常适合,其导轨间可调,各式基板悬空流动,带动基板引走的链条有不锈钢链条、碳钢链条、塑钢链条、导轨及机架有铝型材、不锈钢、碳钢等多种材质,可供选择。主要技术参数.链条节距:25.4mm~203.2mm板链输送机宽度:200mm~800mm(宽度超过800mm时,可使用双板链结构)故障分析.在实际使用中,由于接链环往往比输送链条稍大,磨损情况比较严重,因此接链环成了整个传送链条中的薄弱点。它的损坏形式主要为严重磨损、断裂、拉开,其产生的原因主要为:1、长期承受脉动载荷,疲劳破坏;2、连接销或螺栓松动脱落,未能及时发现补充,致使接链环受力不均或拉托;3、对于立环,单边磨损更为严重,如不及时更换,容易发生断裂;4、卡链后,会产生很大的动载荷和冲击载荷,导致传送链条运动速度的瞬时巨大波动,使传送链条运行不平稳,从而加速接链环磨损或断裂;5、生产制造质量较差,耐磨性差或韧性差硬度低,或者出现应力集中产生疲劳裂纹,导致强度不足。链板输送机的连接环损坏大致就是由于以上五个原因造成的,这要求企业在使用链板输送机时需要定期做好设备的检修工作,发现问题立即进行处理。网带输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机,可分为网带式和网链式。输送机可进行水平、倾斜和垂直输送,也可组成空间输送线路,输送线路一般是固定的。输送机输送能力大,运距长,还可在输送过程中同时完成若干工艺操作.网带输送机制作采用的材质有,碳钢,201不锈钢,304不锈钢。材质.输送带的材质有:碳钢、不锈钢、热塑链,根据您的产品的需要可选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。分类.塑钢网带输送机:是对传统皮带式输送机的补充,它克服了皮带机皮带撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于网带输送机使用模块网带,而且传动方式采用链轮驱动,所以输送网带不易蛇行、跑偏,并且由于带子厚实可以经得起切割、碰撞,及耐油、耐水等特性,使得各业界使用时不致在维修保养上产生困扰,尤其在更换输送带上塑钢网带输送机更减少一笔开销。采用不同材质的网带可以起到不同的输送作用并且满足不同环境的需要,我们通过塑料材质的改性使输送带能够满足环境温度零下-10度至120摄氏度之间的输送要求,网带节距有12.7、19.05、25.4、27.2、38.1、50.8可选,开孔率由2%至48%可选。用途.广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备考虑网带承受拉力限制,长单线长度一般不超过20米。模块式输送机.模块式网带用延伸在输送带整个宽度上的塑料铰接销,把注塑成型的网带组装成互锁单元。这种方法增加了输送带的强度,并可以组接成任何需要的宽度和长度。挡板和侧板也可以用铰接销互锁,成为输送带整体部件之。输送带的材质有: PP(聚丙烯)、PE(聚乙烯)、ACETAL(乙缩醛)、NYLON(尼龙)。结构形式水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。金属网带输送机.采用金属网带作为输送载体。驱动方式减速电机驱动。调速方式变频调速、无极变速。机架材质不锈钢、碳钢。使用范围适用于各行业的烘干、去湿、清洗、速冻等工艺。1、工作原理输送链为套筒滚子链,连续斗式结构,用于高温熟料的水平、爬坡。2、主要特点◆ 输送能力大: 输送能力可达526m3/h,倾角可达60度。耐高温、可输送温度小于600度的物料。◆ 输送链是由牵引链、承载链和正向搭接(或反向搭接)的料斗组成,三部分可自由装卸。◆ 承重的滚轮中带有滚动轴承,以滚动摩擦代替以往的滑动摩擦,运行阻力降低55%-65%,大大减少了输送机的功率消耗,能耗低。◆ 牵引链和承载链分开,使结构简化,成本降低,安装维修方便。◆ 使用寿命长: 牵引链使用长节距、套筒滚子链,链条个零件均采用合金钢材料;并经热处理加工,耐磨。输送部分及物料的重量由承重件承担;链条不再承担重量,减少磨损。◆ 工艺布置多样: 可水平、倾斜,还可以由多段水平、倾斜组合布置。3、适用领域◆ 广泛用于水泥、造纸、制糖、化工等行业。适合用于物料渣浆式、颗粒状等。产品列表.1.移动式输送机 适应运送散装或包装的粮食及小颗粒物料的输送,装卸,码垛,倒仓多种作用,并可由多台串联或用其它机械联合配套使用。可以在露天库内作业。由机架,传动,自动升降装置,托棍,输送带。2.爬坡皮带输送机运用输送带的连续或间歇运动输送500kg以下的物品或粉状、颗装物品。爬坡式皮带输送机运用于有高低差的输送情况下,可完成连续输送,能平滑的与滚筒输送机或链板输送机接驳。3.转弯皮带输送机采用专业的胶带计算程序软件计算出胶带在各个转弯点所受到的拉力,根据这些参数算出各个转弯点及转弯点前后的托辊支架的倾斜角度和托辊倾斜角度,确保胶带在转弯点运行的可靠性。4.柔性输送机柔性输送链板是在传统链板的基本上作了很大改进使链板的运行性能有了质的提高。 输送产品有:皮带输送机,链板输送机,滚筒输送机,网带输送机,链条输送机,柔性输送机。5.皮带输送机运用输送带的连续或间歇运动来输送各种轻重不同的物品,既可输送各种散料,也可输送各种纸箱、包装袋等单件重量不大的件货,用途广泛。6.链板输送机通过制作多排一体,使输送机变的很宽,并形成差速,使多列在无挤压的情况下变为单列,同样也可以使单列变成多列并行走缓慢,从而产生储存量。7.输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机。输送机可进行水平、倾斜和垂直输送,也可组成空间输送线路,输送线路一般是固定的。输送机输送能力大,运距长。8.网带输送机是对传统皮带式输送机的一次革命,它克服皮带输送机维护困难,带子易被撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于此类输送机使用模块式塑料输送带。9.不锈钢输送机全不锈钢结构外形,链板式输送带,无外露紧固件,全新设计,美观大方;输送性能平稳可靠,无极调度,使用方便;用于外观要求好,质量要求高等精密设备的配套使用。10.不锈钢网带输送机采用不锈钢网带作为载体进行输送,适用于各种食品行业的烘干、蒸煮、油炸、去湿、冷冻等及金属行业的冷却、喷淋、清洗、沥油、热处理等工艺。11.网带链输送机:纸箱装啤酒网带链输送机、脱水蔬菜网带链输送机、罐类网带链输送机、蓄电池网带链输送机、轮胎网带链输送机、蔬菜网带链输送机、水产网带链输送机、水果网带链输送机、膨化食品网带链输送机、肉食品小包装网带链输送机、果蔬类网带链输送机、肉类分割网带链输送机。12.铝合金网带输送机采用铝合金网带作为载体进行输送,适用于各种食品,医药,化学品行业。常用带宽.网带输送机的常用带宽有:100毫米,150毫米,200毫米,250毫米,300毫米,400毫米,500毫米,650毫米,800毫米,1000毫米,1200毫米,1400毫米,1600毫米,1800毫米,2000毫米,2200毫米,2400毫米,另外不锈钢网带输送机的输送机网带是一种非标的产品,所以带宽是可以定做的.常用带速.网带输送机的常用带速:0.25米/秒,0.4米/秒,0.5米/秒,0.8米/秒,1.0米/秒,1.25米/秒,1.6米/秒,2.0米/秒,2.5米/秒,3.15米/秒,4.0米/秒,4.5米/秒,5.0米/秒,5.6米/秒,6.5米/秒。日常保养.1、网带输送机在工作过程中应有固定人员看管。看管人员必须是具有一般技术常识及对本输送机的性能比较熟悉。2、企业应制定输送机应"设备维护、检修、操作规程"以便看管人员遵守。看管人员必须有交接班制度。 3、向皮带输送机给料应该均匀,不得给料过多而使进料漏斗被物料塞满而溢出。4、输送机工作过程中,非看管人员不得靠近机器;任何人员不得触摸任何旋转部件。发生故障时,必须立即停止运转,故障。如有不易立即但对工作无过大影响的缺陷,应作记载,待检修时。5、看管输送机时,应经常观察各部件的运行情况,检查各处连接螺栓,发现松动及时拧紧。但禁止输送机运转时,对输送机的运转部件进行清扫和修理。6、尾部装配的螺旋拉紧装置应调整适宜,保持输送带具有正常工作的拉力。看管人员应经常观察输送带的工作情况,局部损坏的地方,应视其破损程度(既是否对生产造成影响)而决定是否立即更换或待检修时更换新的。对拆下的输送带应视其磨损程度而另作它用。7、看管皮带输送机时在于观察其工作状态、清扫、润滑以及检查调整螺旋拉紧装置等零星工作。8、网带输送机一般情况下应在无负荷时起动,在物料卸完后停车。9、输送机除在使用过程中保持正常的润滑和拆换个别损坏的零部件外,每工作6个月必须检修一次。检修时必须在使用中及记载的缺陷,拆换损废零部件及更换润滑油等。10、企业可根据输送机的工作条件制定检修周期。使用方法.在网带输送机运行前,首先要确认网带输送机设备、人员、被输送物品均处于完好的状态;其次检查各运动部位正常,检查所有电气线路是否正常,正常时才能将皮带输送机投入运行。要检查供电电压与设备额定电压的差别不超过±5%。网带输送机的具体操作如下:1.合上总电源开关,检查设备电源是否正常送入且电源指示灯是否亮。正常后进行下一步操作。2.合上各回路的电源开关,检查是否正常。正常状态下为:设备不动作,网带输送机运行指示灯不亮,变频器等设备的电源指示灯亮,变频器的显示面板显示正常。3.按照工艺流程依次启动各电气设备,上一个电气设备启动正常后再进行下一个电气设备的启动。4.在网带输送机运行中,必须遵守被输送物品设计中物品的规定,遵守网带输送机的运送能力。其次,要注意各类人员不得触及网带输送机的运动部分,非专业人员不得随意接触电气元件、控制按钮等。,网带输送机运行中不能对变频器后级断路,如确定维修需要,则必须在停止变频运行的情况下才能进行,否则可能损坏变频器。5.网带输送机运行停止,按下停止按钮待系统全部停止后方能切断总电源。网带输送机的构造原理:采用模块式网带,将输送带整个宽度上的金属铰接销进行延伸,并且将制造成型的网带进行组装构成互锁单元。网带输送机的优点:因结构的特殊性,从而增加了输送带的强度以及可利用性,不论是在宽度上还是在长度上都进行无条件组接。同时网带输送机的挡板与侧板也都可以进行铰接销互锁,成为输送带整体部件之一。网带输送机的材质:可分为碳钢、不锈钢、热塑链。如若所需产品可以选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。网带输送机结构形式有:水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。网带输送机用途:广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备。【网带输送机说明】 网带输送机/网带输送线/网带流水线广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备。适用于各行业的烘干、去湿、清洗、速冻等工艺。·网带材质: 碳钢、不锈钢、PP(聚丙烯)、PE(聚乙烯)、ACETAL(乙缩醛)、NYLON(尼龙)等材料。(某些带型符合FDA、USDA标准,因此广泛用于食品加工业。)·结构形式:水平直线输送、爬坡输送、转弯输送等多种形式,输送带上还可增设挡板、侧板等附件,满足各种工艺需求。·网带输送机小转弯半径:R=W*2.3。·设备特点:1,网带输送克服了污染问题,使用符合卫生标准的塑胶材料一体成型,构造上没有毛细孔及缝隙。输送猪肉、鸡鸭、鱼虾等都不会被产品所带的血水、油脂等污染源渗透,更不会吸附任何杂质于输送带表面。可以达到一个的制造过程;2,塑钢网带输送机是对传统皮带式输送机的补充,它克服了皮带机皮带撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于网带输送机使用模块网带,而且传动方式采用链轮驱动,所以输送网带不易蛇行、跑偏,并且由于带子厚实可以经得起切割、碰撞,及耐油、耐水等特性,使得各业界使用时不致在维修保养上产生困扰,尤其在更换输送带上塑钢网带输送机更减少一笔开销。采用不同材质的网带可以起到不同的输送作用并且满足不同环境的需要,我们通过塑料材质的改性使输送带能够满足环境温度零下-10度至120摄氏度之间的输送要求,网带节距有12.7、19.05、25.4、27.2、38.1、50.8可选,开孔率由2%至48%可选。 螺旋输送机:【螺旋输送机说明】 【标准规格图表】 螺旋输送机,又称螺旋机,螺旋输送线,是冶金、建材、化工、粮食及机械加工等部门广泛应用的一种连续输送设备,与其它输送设备相比,具有整机截面尺寸小、密封性能好、运行平稳可靠、操作、维修简便等优点。·螺旋输送机机身结构材质:碳钢烤漆和不锈钢。·螺旋输送机输送圈数总长度:碳钢底链60米、不锈钢底链48米。 ·螺旋输送机输送宽度:200mm、300mm、400mm、600mm。·螺旋输送机可升降高度:1.单一驱动6米,但依实际运载速度及载重须配合输送圈数总长度而有所变动。2.可多台串联高度达20米。 ·适合行业:饮料、啤酒、卷烟、邮政、报业、印刷、食品、制药、物流、电子等行业。·螺旋输送机(一个电机)承重:碳钢底链<750kg ·不锈钢底链<600kg 螺旋输送机 【规格表】螺旋输送机/螺旋输送线/螺旋流水线 型号 输送宽度 直径 升降高度 。 Net Conveyor Mesh belt conveyor: the modular mesh belt uses the plastic hinge pin extending over the entire width of the conveyor belt to assemble the injection molded mesh belt into an interlocking unit. This method increases the strength of the conveyor belt and can be assembled into any required width and length. The baffle and side plate can also be interlocked with hinged pins to become one of the integral parts of the conveyor belt. The structural forms of mesh belt conveyor include horizontal straight-line transportation, lifting and climbing transportation, etc. the conveyor belt can be added with lifting baffle and side baffle. Plug in line conveyor The plug-in line conveyor adopts special aluminum alloy guide rail. The guide rail on one side close to the operation surface is fixed and the other side can be adjusted and moved to ensure the minimum distance of pickup elements in each operation and improve production efficiency. The equipment is very suitable for the flow operation of electronic substrate. Its guide rails are adjustable, and all kinds of substrates flow in the air. The chains driving the substrate are stainless steel chain, carbon steel chain, plastic steel chain, guide rails and frames are made of aluminum profile, stainless steel, carbon steel and other materials. Main technical parameters Chain pitch: 25.4mm ~ 203.2mm Width of plate chain conveyor: 200mm ~ 800mm (double plate chain structure can be used when the width exceeds 800mm) Fault analysis In practical use, because the chain link is often slightly larger than the conveying chain and the wear is more serious, the chain link has become a weak point in the whole conveying chain. Its damage forms are mainly serious wear, fracture and pulling, and the main causes are: 1. Long term bearing pulsating load, fatigue failure; 2. The connecting pin or bolt is loose and falls off, which is not found and supplemented in time, resulting in uneven stress or pulling support of the connecting link; 3. For the vertical ring, the unilateral wear is more serious. If it is not replaced in time, it is easy to break; 4. After the chain is jammed, great dynamic load and impact load will be generated, resulting in instantaneous and huge fluctuation of the moving speed of the transmission chain, making the transmission chain run unstable, so as to accelerate the wear or fracture of the chain link; 5. Poor manufacturing quality, poor wear resistance or toughness, low hardness, or fatigue cracks due to stress concentration, resulting in insufficient strength. The damage of the connecting ring of the chain plate conveyor is roughly caused by the above five reasons, which requires enterprises to do a good job in equipment maintenance regularly when using the chain plate conveyor, and deal with the problems immediately. Mesh belt conveyor is a material handling machine that continuously transports materials on a certain line, also known as continuous conveyor, which can be divided into mesh belt type and mesh chain type. The conveyor can carry out horizontal, inclined and vertical conveying, and can also form a spatial conveying line. The conveying line is generally fixed. The conveyor has large conveying capacity and long haul distance. It can also complete several process operations at the same time. The materials used for the production of mesh belt conveyor are carbon steel, 201 stainless steel and 304 stainless steel. texture of material. The conveyor belt is made of carbon steel, stainless steel and thermoplastic chain. According to the needs of your products, chain plates with different widths and shapes can be selected to meet the requirements of plane conveying, plane turning, lifting and lowering. Classification Plastic steel mesh belt conveyor: it is a supplement to the traditional belt conveyor. It overcomes the shortcomings of belt tearing, puncture and corrosion of belt conveyor, and provides customers with a safe, fast and simple maintenance transportation mode. Because the mesh belt conveyor uses modular mesh belt, and the transmission mode is driven by sprocket, the conveyor mesh belt is not easy to snake and deviate, and because the belt is thick and can withstand cutting, collision, oil and water resistance, it will not cause trouble in maintenance when used in various industries, especially in replacing the plastic steel mesh belt conveyor on the conveyor belt, which will reduce a sum of expenses. Mesh belts of different materials can play different conveying roles and meet the needs of different environments. Through the modification of plastic materials, the conveyor belt can meet the conveying requirements of the ambient temperature between minus - 10 ℃ and 120 ℃. The mesh belt pitch can be selected from 12.7, 19.05, 25.4, 27.2, 38.1 and 50.8, and the opening rate can be selected from 2% to 48%. Purpose It is widely used in the transportation of beverage bottles, aluminum cans, drugs, cosmetics, food and other industries. By selecting different mesh belts, it can be made into industry-specific equipment such as bottle storage platform, elevator, sterilizer, vegetable cleaning machine, bottle cooling machine and meat food transportation. Considering the tension limit of mesh belt, the maximum single line length is generally no more than 20m. Modular conveyor The modular mesh belt uses a plastic hinge pin extending over the entire width of the conveyor belt to assemble the injection molded mesh belt into an interlocking unit. This method increases the strength of the conveyor belt and can be assembled into any required width and length. The baffle and side plate can also be interlocked with hinged pins to become an integral part of the conveyor belt. The materials of conveyor belt include PP (polypropylene), PE (polyethylene), acetal (acetal) and nylon (nylon). structural style In the form of horizontal straight-line conveying, lifting and climbing conveying, lifting baffle and side baffle can be added to the conveyor belt. Metal mesh belt conveyor The metal mesh belt is used as the conveying carrier. Driving mode Reduction motor drive. Speed regulation mode Variable frequency speed regulation, stepless speed change. Frame material Stainless steel, carbon steel. Scope of use It is suitable for drying, dehumidification, cleaning, quick freezing and other processes in various industries. 1. Working principle The conveyor chain is a sleeve roller chain with continuous bucket structure, which is used for horizontal and climbing of high-temperature clinker. 2. Main features ◆ large conveying capacity: the maximum conveying capacity can reach 526m3 / h and the maximum inclination can reach 60 degrees. High temperature resistant and can transport materials with temperature less than 600 ℃. ◆ the conveying chain is composed of traction chain, bearing chain and hopper with forward lapping (or reverse lapping), and the three parts can be loaded and unloaded freely. ◆ the load-bearing roller is equipped with rolling bearing, which replaces the previous sliding friction with rolling friction, reducing the running resistance by 55% - 65%, greatly reducing the power consumption of the conveyor and low energy consumption. ◆ the traction chain and bearing chain are separated to simplify the structure, reduce the cost and facilitate installation and maintenance. ◆ long service life: the traction chain uses long pitch, sleeve roller chain, and all parts of the chain are made of alloy steel; After heat treatment, it is wear-resistant. The weight of the conveying part and materials shall be borne by the bearing parts; The chain no longer bears weight and reduces wear. ◆ the process layout is diverse: it can be arranged horizontally and obliquely, and can also be combined by multiple sections horizontally and obliquely. 3. Applicable fields ◆ widely used in cement, papermaking, sugar making, chemical industry and other industries. It is most suitable for slurry and granular materials. Product list 1. The mobile conveyor is suitable for the transportation, loading and unloading, palletizing and warehouse transfer of bulk or packaged grain and small particle materials, and can be used by multiple sets in series or combined with other machines. It can work in the open warehouse. It consists of frame, transmission, automatic lifting device, supporting rod and conveyor belt. 2. The climbing belt conveyor uses the continuous or intermittent movement of the conveyor belt to transport articles below 500kg or powdery and granular articles. The climbing belt conveyor is applied to the transportation with height difference. It can complete continuous transportation and can be smoothly connected with roller conveyor or chain plate conveyor. 3. The turning belt conveyor adopts professional belt calculation program software to calculate the tensile force of the belt at each turning point, and calculate the inclination angle of the idler support and idler before and after each turning point according to these parameters, so as to ensure the reliability of belt operation at the turning point. 4. Flexible conveyor flexible conveyor chain plate has made great improvement on the basis of traditional chain plate, so that the operation performance of chain plate has been qualitatively improved. Conveying products include: belt conveyor, chain plate conveyor, roller conveyor, mesh belt conveyor, chain conveyor and flexible conveyor. 5. The belt conveyor uses the continuous or intermittent movement of the conveyor belt to transport all kinds of articles with different weights. It can not only transport all kinds of bulk materials, but also transport all kinds of cartons, bags and other pieces of goods with small single weight, which are widely used. 6. The chain plate conveyor makes the conveyor very wide and forms a differential speed by making multiple rows as a whole, so that multiple rows can become a single row without extrusion. Similarly, a single row can become multiple rows and walk slowly, resulting in storage capacity. 7. Conveyor is a material handling machine that continuously transports materials on a certain line, also known as continuous conveyor. The conveyor can carry out horizontal, inclined and vertical conveying, and can also form a spatial conveying line. The conveying line is generally fixed. The conveyor has large conveying capacity and long haul distance. 8. Mesh belt conveyor is a revolution of traditional belt conveyor. It overcomes the shortcomings of difficult maintenance of belt conveyor and easy tearing, puncture and corrosion of belt. It provides customers with a safe, fast and simple maintenance mode of transportation. Because these conveyors use modular plastic conveyor belts. 9. Stainless steel conveyor, all stainless steel structure and shape, chain plate conveyor belt, no exposed fasteners, new design, beautiful and generous; Stable and reliable conveying performance, stepless scheduling and convenient use; It is used for supporting precision equipment with good appearance and high quality requirements. 10. Stainless steel mesh belt conveyor adopts stainless steel mesh belt as the carrier for transportation. It is suitable for drying, cooking, frying, dehumidification, freezing, etc. in various food industries and cooling, spraying, cleaning, oil drainage, heat treatment and other processes in metal industries. 11. Mesh belt chain conveyor: carton beer mesh belt chain conveyor, dehydrated vegetable mesh belt chain conveyor, tank mesh belt chain conveyor, battery mesh belt chain conveyor, tire mesh belt chain conveyor, vegetable mesh belt chain conveyor, aquatic mesh belt chain conveyor, fruit mesh belt chain conveyor, expanded food mesh belt chain conveyor, meat food small packaging mesh belt chain conveyor Fruit and vegetable mesh belt chain conveyor, meat segmentation mesh belt chain conveyor. 12. Aluminum alloy mesh belt conveyor adopts aluminum alloy mesh belt as carrier for transportation, which is suitable for all kinds of food, medicine and chemical industries. Common bandwidth The most commonly used belt widths of mesh belt conveyors are: 100 mm, 150 mm, 200 mm, 250 mm, 300 mm, 400 mm, 500 mm, 650 mm, 800 mm, 1000 mm, 1200 mm, 1400 mm, 1600 mm, 1800 mm, 2000 mm, 2200 mm, 2400 mm. In addition, the conveyor mesh belt of stainless steel mesh belt conveyor is a non-standard product, So the bandwidth can be customized Common belt speed The most commonly used belt speeds of mesh belt conveyors: 0.25m/s, 0.4m/s, 0.5m/s, 0.8m/s, 1.0m/s, 1.25m/s, 1.6m/s, 2.0m/s, 2.5m/s, 3.15m/s, 4.0m/s, 4.5m/s, 5.0m/s, 5.6m/s, 6.5m/s. Daily maintenance 1. The mesh belt conveyor shall be watched by fixed personnel during operation. The caretaker must have general technical knowledge and be familiar with the performance of the conveyor. 2. The enterprise shall formulate "equipment maintenance, overhaul and safe operation procedures" for the conveyor to be observed by the caretaker. The caretaker must have a shift system. 3. The feeding to the belt conveyor shall be uniform, and the feeding funnel shall not be filled with materials and overflow due to excessive feeding. 4. During the operation of the conveyor, non caretaker personnel shall not approach the machine; No person shall touch any rotating parts. In case of failure, the operation must be stopped immediately to eliminate the failure. If there are defects that are not easy to eliminate immediately but have no great impact on the work, they shall be recorded and eliminated during maintenance. 5. When taking care of the conveyor, always observe the operation of all parts, check the connecting bolts everywhere, and tighten them in time if they are loose. However, it is absolutely forbidden to clean and repair the running parts of the conveyor when the conveyor is running. 6. The screw tensioning device assembled at the tail shall be adjusted appropriately to keep the conveyor belt with normal working tension. The caretaker shall often observe the working condition of the conveyor belt. For local damage, it shall decide whether to replace it immediately or replace it when it is to be repaired according to its damage degree (i.e. whether it will affect the production). The removed conveyor belt shall be used for other purposes according to its wear degree. 7. When taking care of the belt conveyor, it is necessary to observe its working state, clean, lubricate, check and adjust the screw tensioning device and other sporadic work. 8. Generally, the mesh belt conveyor shall be started when there is no load and stopped after the materials are unloaded. 9. In addition to maintaining normal lubrication and replacing individual damaged parts during use, the conveyor must be overhauled every 6 months. During maintenance, the defects in use and recorded must be eliminated, and the damaged waste parts and components and lubricating oil must be replaced. 10. The enterprise can formulate the maintenance cycle according to the working conditions of the conveyor. usage method. Before the operation of the mesh belt conveyor, first confirm that the equipment, personnel and transported articles of the mesh belt conveyor are in a safe and intact state; Secondly, check whether all moving parts are normal and whether all electrical circuits are normal. Only when they are normal can the belt conveyor be put into operation. Finally, check that the difference between the power supply voltage and the rated voltage of the equipment does not exceed ± 5%. The specific operation of mesh belt conveyor is as follows: 1. Close the main power switch and check whether the equipment power is normally supplied and whether the power indicator is on. Proceed to the next step after normal operation. 2. Close the power switch of each circuit and check whether it is normal. Under normal conditions: the equipment does not act, the operation indicator of mesh belt conveyor does not light, the power indicator of frequency converter and other equipment is light, and the display panel of frequency converter is normal. 3. Start all electrical equipment in sequence according to the process flow. Start the next electrical equipment after the previous electrical equipment starts normally. 4. During the operation of the mesh belt conveyor, the provisions of the articles to be transported in the design and the transportation capacity of the mesh belt conveyor must be observed. Secondly, it should be noted that all kinds of personnel shall not touch the moving part of the mesh belt conveyor, and non professionals shall not touch electrical components, control buttons, etc. at will. Finally, during the operation of the mesh belt conveyor, the rear stage of the frequency converter cannot be opened. If the maintenance needs are determined, it must be carried out when the frequency conversion operation is stopped, otherwise the frequency converter may be damaged. 5. When the mesh belt conveyor stops running, press the stop button and cut off the main power supply after all the systems stop. Structural principle of mesh belt conveyor: modular mesh belt is adopted to extend the metal hinge pin on the whole width of the conveyor belt, and the manufactured mesh belt is assembled to form an interlocking unit. Advantages of mesh belt conveyor: due to the particularity of structure, the strength and availability of conveyor belt are increased. Unconditional assembly is carried out both in width and length. At the same time, the baffle and side plate of the mesh belt conveyor can also be interlocked with hinge pins, which becomes one of the integral parts of the conveyor belt. Material of mesh belt conveyor: it can be divided into carbon steel, stainless steel and thermoplastic chain. If required, chain plates with different widths and shapes can be selected to meet the requirements of plane conveying, plane turning, lifting and lowering. The structural forms of mesh belt conveyor include horizontal straight-line transportation, lifting and climbing transportation, etc. the conveyor belt can be added with lifting baffle and side baffle. Purpose of mesh belt conveyor: it is widely used in the transportation of beverage bottles, aluminum cans, drugs, cosmetics, food and other industries. By selecting different mesh belts, it can be made into industry-specific equipment such as bottle storage platform, elevator, sterilizer, vegetable cleaning machine, bottle cooling machine and meat food transportation. [description of mesh belt conveyor] Mesh belt conveyor / mesh belt conveyor line / mesh belt assembly line are widely used in beverage bottles, aluminum cans, drugs, cosmetics and food

网带输送机 网带输送机:模块式网带用延伸在输送带整个宽度上的塑料铰接销,把注塑成型的网带组装成互锁单元。这种方法增加了输送带的强度,并可以组接成任何需要的宽度和长度。挡板和侧板也可以用铰接销互锁,成为输送带整体部件之一。 网带输送机结构形式有:水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。 插件线输送机 插件线输送机采用专用铝合金导轨,靠近操作面一边的导轨固定,另一边可调节移动,保证操作每一次拾取元件距离小,提高生产效率。该设备对于电子基板的流水作业非常适合,其导轨间可调,各式基板悬空流动,带动基板引走的链条有不锈钢链条、碳钢链条、塑钢链条、导轨及机架有铝型材、不锈钢、碳钢等多种材质,可供选择。 主要技术参数. 链条节距:25.4mm~203.2mm 板链输送机宽度:200mm~800mm (宽度超过800mm时,可使用双板链结构) 故障分析. 在实际使用中,由于接链环往往比输送链条稍大,磨损情况比较严重,因此接链环成了整个传送链条中的薄弱点。它的损坏形式主要为严重磨损、断裂、拉开,其产生的原因主要为: 1、长期承受脉动载荷,疲劳破坏; 2、连接销或螺栓松动脱落,未能及时发现补充,致使接链环受力不均或拉托; 3、对于立环,单边磨损更为严重,如不及时更换,容易发生断裂; 4、卡链后,会产生很大的动载荷和冲击载荷,导致传送链条运动速度的瞬时巨大波动,使传送链条运行不平稳,从而加速接链环磨损或断裂; 5、生产制造质量较差,耐磨性差或韧性差硬度低,或者出现应力集中产生疲劳裂纹,导致强度不足。 链板输送机的连接环损坏大致就是由于以上五个原因造成的,这要求企业在使用链板输送机时需要定期做好设备的检修工作,发现问题立即进行处理。 网带输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机,可分为网带式和网链式。输送机可进行水平、倾斜和垂直输送,也可组成空间输送线路,输送线路一般是固定的。输送机输送能力大,运距长,还可在输送过程中同时完成若干工艺操作.网带输送机制作采用的材质有,碳钢,201不锈钢,304不锈钢。 材质. 输送带的材质有:碳钢、不锈钢、热塑链,根据您的产品的需要可选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。 分类. 塑钢网带输送机:是对传统皮带式输送机的补充,它克服了皮带机皮带撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于网带输送机使用模块网带,而且传动方式采用链轮驱动,所以输送网带不易蛇行、跑偏,并且由于带子厚实可以经得起切割、碰撞,及耐油、耐水等特性,使得各业界使用时不致在维修保养上产生困扰,尤其在更换输送带上塑钢网带输送机更减少一笔开销。采用不同材质的网带可以起到不同的输送作用并且满足不同环境的需要,我们通过塑料材质的改性使输送带能够满足环境温度零下-10度至120摄氏度之间的输送要求,网带节距有12.7、19.05、25.4、27.2、38.1、50.8可选,开孔率由2%至48%可选。 用途. 广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备考虑网带承受拉力限制,长单线长度一般不超过20米。 模块式输送机. 模块式网带用延伸在输送带整个宽度上的塑料铰接销,把注塑成型的网带组装成互锁单元。这种方法增加了输送带的强度,并可以组接成任何需要的宽度和长度。挡板和侧板也可以用铰接销互锁,成为输送带整体部件之。 输送带的材质有: PP(聚丙烯)、PE(聚乙烯)、ACETAL(乙缩醛)、NYLON(尼龙)。 结构形式 水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。 金属网带输送机. 采用金属网带作为输送载体。 驱动方式 减速电机驱动。 调速方式 变频调速、无极变速。 机架材质 不锈钢、碳钢。 使用范围 适用于各行业的烘干、去湿、清洗、速冻等工艺。 1、工作原理 输送链为套筒滚子链,连续斗式结构,用于高温熟料的水平、爬坡。 2、主要特点 ◆ 输送能力大: 输送能力可达526m3/h,倾角可达60度。耐高温、可输送温度小于600度的物料。 ◆ 输送链是由牵引链、承载链和正向搭接(或反向搭接)的料斗组成,三部分可自由装卸。 ◆ 承重的滚轮中带有滚动轴承,以滚动摩擦代替以往的滑动摩擦,运行阻力降低55%-65%,大大减少了输送机的功率消耗,能耗低。 ◆ 牵引链和承载链分开,使结构简化,成本降低,安装维修方便。 ◆ 使用寿命长: 牵引链使用长节距、套筒滚子链,链条个零件均采用合金钢材料;并经热处理加工,耐磨。输送部分及物料的重量由承重件承担;链条不再承担重量,减少磨损。 ◆ 工艺布置多样: 可水平、倾斜,还可以由多段水平、倾斜组合布置。 3、适用领域 ◆ 广泛用于水泥、造纸、制糖、化工等行业。适合用于物料渣浆式、颗粒状等。 产品列表. 1.移动式输送机 适应运送散装或包装的粮食及小颗粒物料的输送,装卸,码垛,倒仓多种作用,并可由多台串联或用其它机械联合配套使用。可以在露天库内作业。由机架,传动,自动升降装置,托棍,输送带。 2.爬坡皮带输送机运用输送带的连续或间歇运动输送500kg以下的物品或粉状、颗装物品。爬坡式皮带输送机运用于有高低差的输送情况下,可完成连续输送,能平滑的与滚筒输送机或链板输送机接驳。 3.转弯皮带输送机采用专业的胶带计算程序软件计算出胶带在各个转弯点所受到的拉力,根据这些参数算出各个转弯点及转弯点前后的托辊支架的倾斜角度和托辊倾斜角度,确保胶带在转弯点运行的可靠性。 4.柔性输送机柔性输送链板是在传统链板的基本上作了很大改进使链板的运行性能有了质的提高。 输送产品有:皮带输送机,链板输送机,滚筒输送机,网带输送机,链条输送机,柔性输送机。 5.皮带输送机运用输送带的连续或间歇运动来输送各种轻重不同的物品,既可输送各种散料,也可输送各种纸箱、包装袋等单件重量不大的件货,用途广泛。 6.链板输送机通过制作多排一体,使输送机变的很宽,并形成差速,使多列在无挤压的情况下变为单列,同样也可以使单列变成多列并行走缓慢,从而产生储存量。 7.输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机。输送机可进行水平、倾斜和垂直输送,也可组成空间输送线路,输送线路一般是固定的。输送机输送能力大,运距长。 8.网带输送机是对传统皮带式输送机的一次革命,它克服皮带输送机维护困难,带子易被撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于此类输送机使用模块式塑料输送带。 9.不锈钢输送机全不锈钢结构外形,链板式输送带,无外露紧固件,全新设计,美观大方;输送性能平稳可靠,无极调度,使用方便;用于外观要求好,质量要求高等精密设备的配套使用。 10.不锈钢网带输送机采用不锈钢网带作为载体进行输送,适用于各种食品行业的烘干、蒸煮、油炸、去湿、冷冻等及金属行业的冷却、喷淋、清洗、沥油、热处理等工艺。 11.网带链输送机:纸箱装啤酒网带链输送机、脱水蔬菜网带链输送机、罐类网带链输送机、蓄电池网带链输送机、轮胎网带链输送机、蔬菜网带链输送机、水产网带链输送机、水果网带链输送机、膨化食品网带链输送机、肉食品小包装网带链输送机、果蔬类网带链输送机、肉类分割网带链输送机。 12.铝合金网带输送机采用铝合金网带作为载体进行输送,适用于各种食品,医药,化学品行业。 常用带宽. 网带输送机的常用带宽有:100毫米,150毫米,200毫米,250毫米,300毫米,400毫米,500毫米,650毫米,800毫米,1000毫米,1200毫米,1400毫米,1600毫米,1800毫米,2000毫米,2200毫米,2400毫米,另外不锈钢网带输送机的输送机网带是一种非标的产品,所以带宽是可以定做的. 常用带速. 网带输送机的常用带速:0.25米/秒,0.4米/秒,0.5米/秒,0.8米/秒,1.0米/秒,1.25米/秒,1.6米/秒,2.0米/秒,2.5米/秒,3.15米/秒,4.0米/秒,4.5米/秒,5.0米/秒,5.6米/秒,6.5米/秒。 日常保养. 1、网带输送机在工作过程中应有固定人员看管。看管人员必须是具有一般技术常识及对本输送机的性能比较熟悉。 2、企业应制定输送机应"设备维护、检修、操作规程"以便看管人员遵守。看管人员必须有交接班制度。 3、向皮带输送机给料应该均匀,不得给料过多而使进料漏斗被物料塞满而溢出。 4、输送机工作过程中,非看管人员不得靠近机器;任何人员不得触摸任何旋转部件。发生故障时,必须立即停止运转,故障。如有不易立即但对工作无过大影响的缺陷,应作记载,待检修时。 5、看管输送机时,应经常观察各部件的运行情况,检查各处连接螺栓,发现松动及时拧紧。但禁止输送机运转时,对输送机的运转部件进行清扫和修理。 6、尾部装配的螺旋拉紧装置应调整适宜,保持输送带具有正常工作的拉力。看管人员应经常观察输送带的工作情况,局部损坏的地方,应视其破损程度(既是否对生产造成影响)而决定是否立即更换或待检修时更换新的。对拆下的输送带应视其磨损程度而另作它用。 7、看管皮带输送机时在于观察其工作状态、清扫、润滑以及检查调整螺旋拉紧装置等零星工作。 8、网带输送机一般情况下应在无负荷时起动,在物料卸完后停车。 9、输送机除在使用过程中保持正常的润滑和拆换个别损坏的零部件外,每工作6个月必须检修一次。检修时必须在使用中及记载的缺陷,拆换损废零部件及更换润滑油等。 10、企业可根据输送机的工作条件制定检修周期。 使用方法. 在网带输送机运行前,首先要确认网带输送机设备、人员、被输送物品均处于完好的状态;其次检查各运动部位正常,检查所有电气线路是否正常,正常时才能将皮带输送机投入运行。要检查供电电压与设备额定电压的差别不超过±5%。 网带输送机的具体操作如下: 1.合上总电源开关,检查设备电源是否正常送入且电源指示灯是否亮。正常后进行下一步操作。 2.合上各回路的电源开关,检查是否正常。正常状态下为:设备不动作,网带输送机运行指示灯不亮,变频器等设备的电源指示灯亮,变频器的显示面板显示正常。 3.按照工艺流程依次启动各电气设备,上一个电气设备启动正常后再进行下一个电气设备的启动。 4.在网带输送机运行中,必须遵守被输送物品设计中物品的规定,遵守网带输送机的运送能力。其次,要注意各类人员不得触及网带输送机的运动部分,非专业人员不得随意接触电气元件、控制按钮等。,网带输送机运行中不能对变频器后级断路,如确定维修需要,则必须在停止变频运行的情况下才能进行,否则可能损坏变频器。 5.网带输送机运行停止,按下停止按钮待系统全部停止后方能切断总电源。 网带输送机的构造原理:采用模块式网带,将输送带整个宽度上的金属铰接销进行延伸,并且将制造成型的网带进行组装构成互锁单元。 网带输送机的优点:因结构的特殊性,从而增加了输送带的强度以及可利用性,不论是在宽度上还是在长度上都进行无条件组接。同时网带输送机的挡板与侧板也都可以进行铰接销互锁,成为输送带整体部件之一。 网带输送机的材质:可分为碳钢、不锈钢、热塑链。如若所需产品可以选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。 网带输送机结构形式有:水平直线输送、爬坡输送等形式,输送带可增设挡板、侧挡板。 网带输送机用途:广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备。 【网带输送机说明】 网带输送机/网带输送线/网带流水线广泛应用于饮料瓶、铝罐、药品、、食品等行业的输送,通过选用不同的网带可以制作成储瓶台、机、杀菌机、蔬菜清洗机、冷瓶机以及肉食品输送等行业专用设备。适用于各行业的烘干、去湿、清洗、速冻等工艺。 ·网带材质: 碳钢、不锈钢、PP(聚丙烯)、PE(聚乙烯)、ACETAL(乙缩醛)、NYLON(尼龙)等材料。(某些带型符合FDA、USDA标准,因此广泛用于食品加工业。) ·结构形式:水平直线输送、爬坡输送、转弯输送等多种形式,输送带上还可增设挡板、侧板等附件,满足各种工艺需求。 ·网带输送机小转弯半径:R=W*2.3。 ·设备特点:1,网带输送克服了污染问题,使用符合卫生标准的塑胶材料一体成型,构造上没有毛细孔及缝隙。输送猪肉、鸡鸭、鱼虾等都不会被产品所带的血水、油脂等污染源渗透,更不会吸附任何杂质于输送带表面。可以达到一个的制造过程;2,塑钢网带输送机是对传统皮带式输送机的补充,它克服了皮带机皮带撕裂、刺破、腐蚀的缺点,为客户提供的一种、快捷、维护简单的输送方式。由于网带输送机使用模块网带,而且传动方式采用链轮驱动,所以输送网带不易蛇行、跑偏,并且由于带子厚实可以经得起切割、碰撞,及耐油、耐水等特性,使得各业界使用时不致在维修保养上产生困扰,尤其在更换输送带上塑钢网带输送机更减少一笔开销。采用不同材质的网带可以起到不同的输送作用并且满足不同环境的需要,我们通过塑料材质的改性使输送带能够满足环境温度零下-10度至120摄氏度之间的输送要求,网带节距有12.7、19.05、25.4、27.2、38.1、50.8可选,开孔率由2%至48%可选。 螺旋输送机: 【螺旋输送机说明】 【标准规格图表】 螺旋输送机,又称螺旋机,螺旋输送线,是冶金、建材、化工、粮食及机械加工等部门广泛应用的一种连续输送设备,与其它输送设备相比,具有整机截面尺寸小、密封性能好、运行平稳可靠、操作、维修简便等优点。 ·螺旋输送机机身结构材质:碳钢烤漆和不锈钢。 ·螺旋输送机输送圈数总长度:碳钢底链60米、不锈钢底链48米。 ·螺旋输送机输送宽度:200mm、300mm、400mm、600mm。 ·螺旋输送机可升降高度:1.单一驱动6米,但依实际运载速度及载重须配合输送圈数总长度而有所变动。2.可多台串联高度达20米。 ·适合行业:饮料、啤酒、卷烟、邮政、报业、印刷、食品、制药、物流、电子等行业。 ·螺旋输送机(一个电机)承重:碳钢底链<750kg ·不锈钢底链<600kg 螺旋输送机 【规格表】螺旋输送机/螺旋输送线/螺旋流水线 型号 输送宽度 直径 升降高度 YY-LX-400-1300 400 1740mm 6500mm YY-LX-600-1500 600 2240mm 6500mm

浩宇输送机械制造厂

水平网带输送机订制_浩宇输送机械制造厂,固定电话:17853417888,移动电话:0534-5813888,联系人:许经理,QQ:732358124,经济开发区泰山路南首路西 发货到 河北省。