想要深入了解柔性链板输送机报价产品的各项功能和特点?我们为您准备了精彩视频,不容错过!

以下是:柔性链板输送机报价的图文介绍

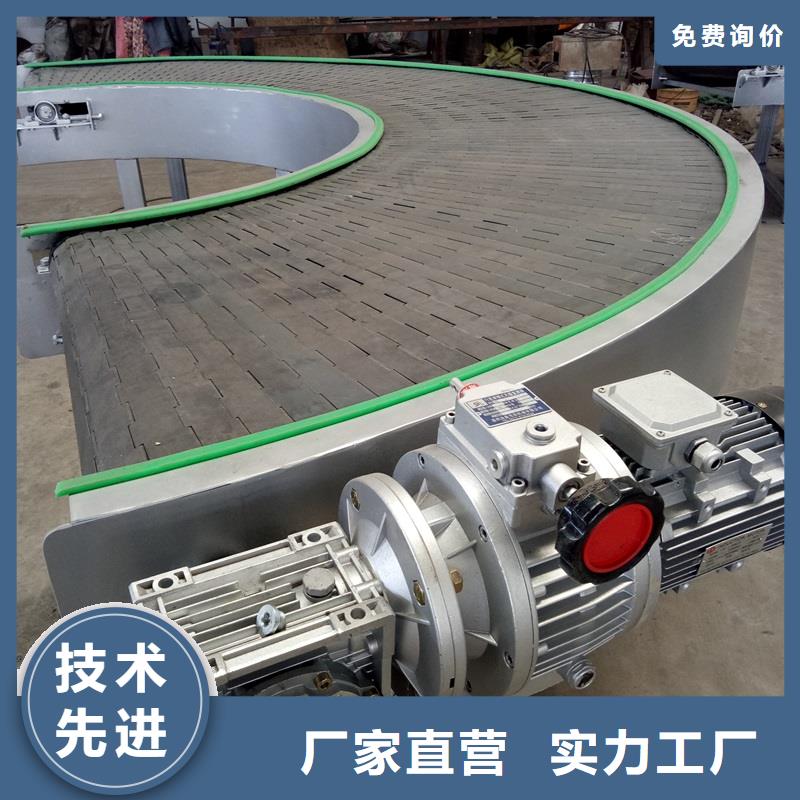

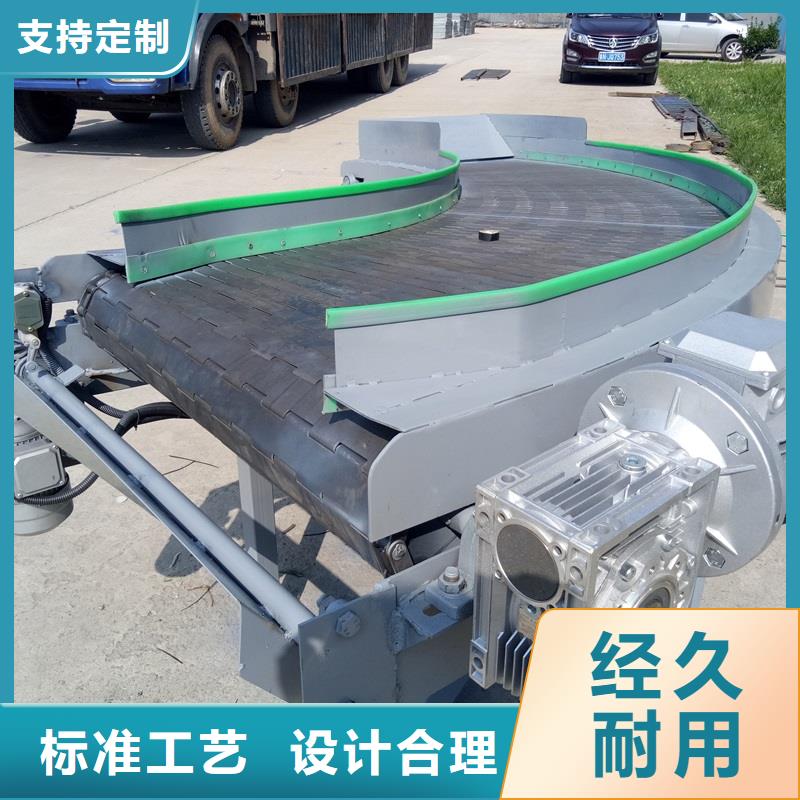

山西转弯机生产制作经验品质好放心选择

山西转弯机的详细介绍

诚信放心工厂直销

浩宇输送机械制造厂成立于2007年,拥有自主研发生产等部门,为不断满足 山西转弯机市场与客户的需求,公司不断引进专业的研发人才及先进的生产设备。可按客户要求研发生产各系列 山西转弯机产品。为保证产品品质,公司制定有一系列完整的生产工艺规范,及对所有供应商与物料都有严格的甄选与管控制度。以限度从源头管控品质,确保所有物料及工艺均符合相关的标准要求。公司的目标就在于通过持续提供新产品响应市场需求,坚持以“诚信为本,以质取胜”的经营理念,奉行“客户至上”的经营方针,已得到客户广泛的认同和信任。竭诚为广大新老客户提供优质的 山西转弯机产品、完善的服务,而保持行业地位。

浩宇输送机械制造厂

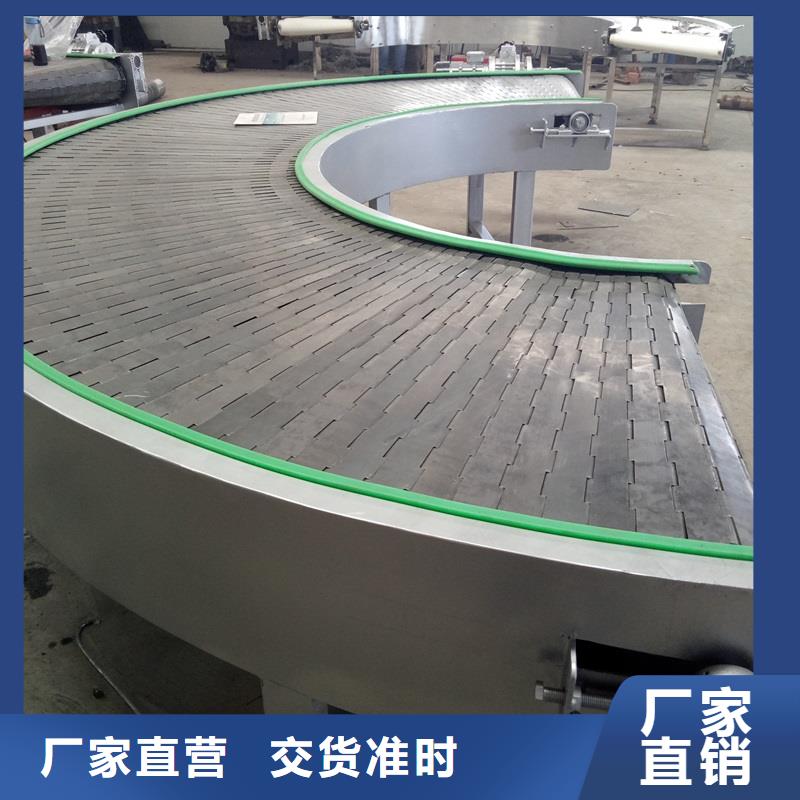

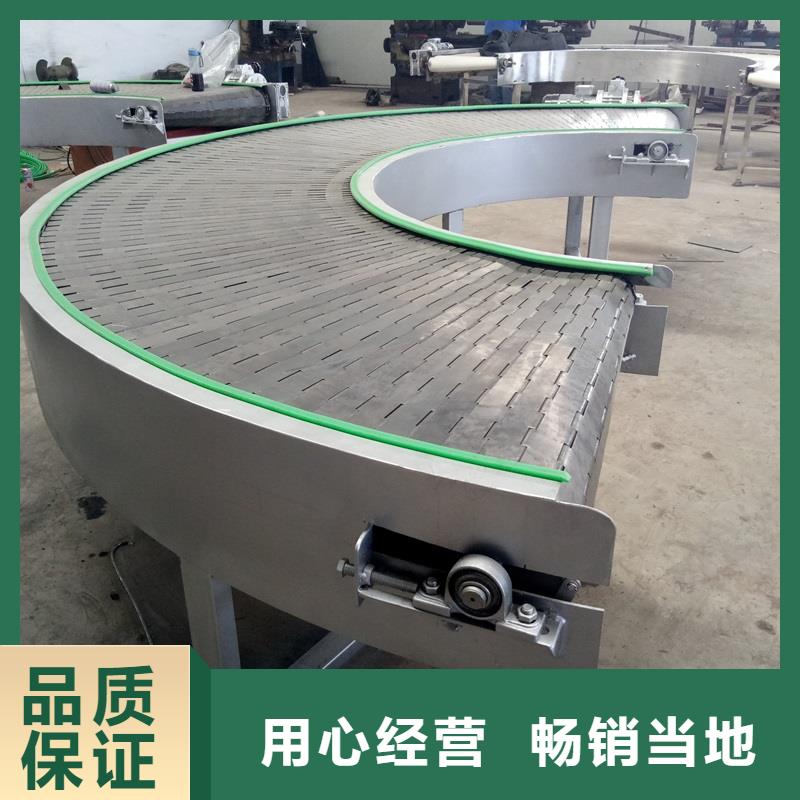

产品实拍图片

从事山西转弯机行业多年品质值得信赖

链板输送机以标准链板为承载面,由马达减速机为动力传动;我们可以通过多列链板并行,使链板输送机做的很宽并形成差速,利用多列链板的速度差使多列输送在无挤压的情况下变为单列输送,从而满足饮料贴标、灌装、清洗等设备的单列输送的要求,我们可以将两条链板输送机的头尾部做成重叠式的混合链使得瓶(罐)体处于动态过度状态,使输送线上不滞留物料,可以满足空瓶以及实瓶压力和无压力输送。概述.链板输送机链板规格:直输链板宽度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;转弯链板宽度有82.5、114.3、152.4、190.5、304.8。特点.1、链板输送机的输送面平坦光滑、摩擦力小,物料在输送线之间的过渡平稳,可输送各类玻璃瓶、PET瓶、易拉罐等物料,也可输送各类箱包;2、链板有不锈钢和工程塑料等材质、规格品种繁多,可根据输送物料和工艺要求选用,能满足各行各业不同的需求;3、机架材质分铝型材、普通碳钢、不锈钢。4、输送能力大,可承载较大的载荷,如用于电动车、摩托车、发电机等行业;5、输送速度准确稳定,能保证的同步输送;6、链板输送机一般都可以直接用水冲洗或直接浸泡在水中,设备清洁方便,能满足食品、饮料行业对卫生的要求;7、设备布局灵活。可以在一条输送线上完成水平、倾斜和转弯输送;8、设备结构简单,维护方便。应用.应用:直输链板宽度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;转弯链板宽度有82.5、114.3、152.4、190.5、304.8,广泛用于食品、罐头、药品、饮料、和洗涤用品、纸制品、调味品、乳业及烟草等的自动输送、分配、和后道包装的连线输送。输送链板有POM材质和不锈钢及不锈铁3种,转弯形式有带翼转弯和磁性转弯2种。转弯链板输送机采用π型转弯链板作为输送载体,链板运行在高分子聚甲醛制作的专用转弯导轨里;或使用不锈钢转弯链板并使用带磁性的转弯导轨,使输送链板始终运行在专用导轨里面,具有运行平稳,安装方便的特点;分类.链式输送机主要分为链板输送机、悬挂链输送机、网带输送机、插件线输送机四大类。设备简介链板输送机可以满足饮料贴标、灌装、清洗等设备的单列输送的要求,同样也可以使单列变成多列并行走缓慢,从而产生储存量,满足杀菌机、储瓶台、冷瓶机的大量供料的要求,我们可以将两条链板输送机的头尾部做成重叠式的混合链,使得瓶(罐)体处于动态过度状态,使输送线上不滞留瓶子,可以满足空瓶及实瓶的压力和无压力输送。链板材质:碳钢、不锈钢、热塑链,根据您的产品的需要可选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。链板规格:直输链板宽度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;转弯链板宽度有82.5、114.3、152.4、190.5、304.8。悬挂链输送机悬挂链是一种三维空间闭环连续输送系统,适用于车间内部和车间之间成件物品的自动化输送。根据输送物件的方法,可分为通用和轻型的牵引式悬挂输送、通用积放式和轻型积放式的推式悬挂输送。 悬挂链,采用滚珠轴承作为链条走轮,导轨均选用16Mn材质经过深加工而成,使用寿命在5年以上。链条节距常用的有150/200/240/250等,单点承重也各不一样。同时通过选择吊具类型,可增加链条的单点承重。该输送线能随意转弯、爬升,能适应各种地理环境条件。该输送线主要用在车间内的物料空中配送上,设计合理的方案,能将仓库、装配线等相关节点有机的结合起来,可在程度上理顺车间的物流,产生更大的效益。该输送线也能用作摩托车车架的部装,以及喷涂设备的烘干输送设备。链板输送机的使用注意事项.链板输送机在饮料行业不仅给人们节约了时间,还带来了方便,一个小小的输送过程既满足了饮料贴标、灌装、清洗等要求,还有杀菌和存储的作用。可是链板输送机在使用的时候有些地方需要工作人员注意,如下:1、链板输送机在运输过程中运输和储存在物品运输和储存过程中注意不能和酸碱、油、水等污染物接触,并且要远离热源;避免长期阳光直射和雨雪浸淋;储存温度应保持在–100C-400C,相对湿度应保持在50%-80%。运输和储存过程中不得挤压、碰撞。2、链板输送机的吊装在使用吊车搬运链板输送机的时候,采用绳索和钢棒起吊的方式。先把一钢棒穿过带芯轴孔,并将带有撑杆的绳索吊住钢棒两端将带吊起。吊运时,注意勿使绳索损伤带边。在没有钢棒和撑杆的情况下,亦可将一具有足够强度的织物绳索穿过芯轴孔起吊。但在绳索和带接触的地方,应垫一物体,防止绳索勒坏带边。不得将吊具插入带卷内起吊,不得将绳索绕在带卷上起吊,防止带卷向一边滑脱。也可使用有足够承载能力的叉车搬吊,但不得使带的外圈损伤。链板输送机的日常维护.链板生产线设备清洁方便,线体可以直接用水冲洗设备的表面(但需注意动力部分及控制部分则不可用水清洗,以免损坏内部部件,触电,发生意外事故。)要想使设备的使用寿命达到值,维护与保养才是关键。一般而言,动力部分的马达在使用一年左右就需及时更换机油,以保证马达处在运行状态,减少内部的损耗。平时在链板生产线设备使用完后,要及时关闭电源,一段时间对设备表面进行清洁。设备需要维护时,应该由专业设备人员进行维护,非相关人员不要进行,以免发生造成不必要的经济损失和事故。设备发生故障时不可盲目检查维修,应让专业工程人员来进行检查维修。在输送机运转过程中,链板生产线遭受各种不一样性质和体积的裁荷效用,居于极复杂的应力状况下。链板生产线典型的毁坏方式有:工作面层和边缘磨耗;受大块矿岩冲击效用引动击穿、撕裂和脱落;芯体经过短笛和托辊组受反反复复屈曲应力引动疲乏;在背景媒介效用下,引动强度指标减低和老化等等。链板输送机:又叫链板传送机,链板线。是一种利用循环往复的链条作为牵引动力,以金属板作为输送承载体的一种输送机械设备。国内市场上有两种链板输送机,一种是用链条,支轴和金属板组成的输送链板做成的输送机;一种是用带弯板的链条和金属板组成的金属板输送带做成的链板输送机。链板式输送机应用于重件的输送,常用于各类摩托车、汽车总装输送线及焊接输送机,各类制动器、发动机链板输送机、起动机链板机、磁电器门链板输送机、发电机链板输送机、电焊机链板输送机等装配。输送机为摩托车链板输送机整车制造装配厂商必不可少的设备,通过流水线操作,对工厂的装配工艺进行有效的调整,合理分配每道工序;并可在输送机上随意添置在线检测及自动装配专机,实施有效的产品质量控制及设备运行状态监控,为现代化的大生产提供必要的保障。输送机采用大节距滚针弯板链为输送介质,拖动金属面板作循环往复运行,链板输送线的速度可调。有照明、风扇、工装板等标准配置。根据产量对线体的长度进行选择。链板输送线是以大节距特种弯板链条为传送介质,带动金属/塑料面板作循环往复运行的一种输送装配设备。由于线体结构及输送介质较为坚固,所以一般用在较重物品的输送和装配作业现场,每米的承重可达到500Kg。线体的输送速度可调,有电磁调速、变频调速、机械调速等各种调速方式,一般快速度在15M/min以内。由于工作环境以及生产工艺的需要,该线体也可做成90度或180度转弯型的,用在空调链板输送机、冰箱链板链板机、电动工具链板输送机等的抽真空、检测上。在面板上可设置各种工装夹具,以满足工件的夹紧、旋转及装配、检测等。在需要对工件表面进行防护的,面板可采用塑料材质或是在金属面板表面贴胶。线体的主体结构主要有钢架结构和铝型材结构两种。传送链条的节距从38.1mm到200mm可供选择。是重型物品输送装配作业现场为理想的设备。链板式输送机,利用固接在牵引链上的一系列链板在水平或倾斜方向输送物料的输送机,以单片钢板铰接成环带作为运输机的牵引和承载构件承载面具有横向隔片置于槽箱中驱动环带借隔片将煤刮运输出。它由驱动机构、张紧装置、牵引链、板条、驱动及改向链轮、机架等部分组成。在冶金、煤炭、化工、电力、机械制造及国民经济的其他工业部门中均得到了广泛的应用。特点.1、适用范围广。除粘度特别大的物料外,一般固态物料和成件物均可用它输送;2、输送能力大;3、牵引链的强度高,可用作长距离输送;4、输送线路布置灵活。与网带式输送机相比,链板式输送机可在较大的倾角和较小的弯曲半径的条件下输送,因此布置的灵活性较大。链板式输送机的倾角可达30°-35°,弯曲半径一般约为5-8m;5、在输送过程中可进行分类、干燥、冷却或装配等各种工艺加工;6、运行平稳可靠;分类.1、链板式输送机的结构型式多样。链板式输送机一般可按下述分类:2、按输送机的安装形式可分为固定式和移动式;3、按输送机的布置形式可分为水平型、水平-倾斜型、倾斜型、倾斜-水平型、水平-倾斜-水平型等;4、按牵引构件的结构型式可分为套筒滚子链式、冲压链式、铸造链式、环链式及可拆链式等;5、按牵引链的数量可分为单链式和双链式;6、按底板的结构型式可分为鳞板式(有挡边波浪型,无挡边波浪型,有挡边深型等)和平板式(有挡边平型和无挡边平型等);7、按输送机的运行特征可分为连续式和脉动式;8、按驱动方式可分为电力机械驱动式及液力驱动式。特点.占地面积小,伸缩自如;*方向易变,可灵活改变输送方向,时可达到180度;*S型辊道输送机,每单元由8只辊筒组成,每一个单元都可独立使用,也可多个单元联接使用,安装方便;*S型辊道输送机伸缩自如,一个单元长与短状态之比可达到3倍;*S型辊道输送机可灵活改变输送方向,时可以大于180度。滚筒输送机适用于各类箱、包、托盘等件货的输送,散料、小件物品或不规则的物品需放在托盘上或周转箱内输送。能够输送单件重量很大的物料,或承受较大的冲击载荷。结构形式:按驱动方式可分为动力滚筒线和无动力滚筒线,按布置形式可分为水平输送滚筒线、倾斜输送滚筒 线和转弯滚筒线。还可按客户要求特殊设计,以满足各类客户的要求。标准规滚筒线内宽度为200、300、400、500、1200mm等。也可按客户需求 采用其它特殊规格。转弯滚筒线标准转弯内半径为600、900、1200mm等,也可按客户需求采用其它特殊规格。直段滚筒所用的滚筒直径有38、50、 60、76、89mm等。特点1、链板输送机的输送面平坦光滑、摩擦力小,物料在输送线之间的过渡平稳,可输送各类玻璃瓶、PET瓶、易拉罐等物料,也可输送各类箱包 ;2、链板有不锈钢和工程塑料等材质、规格品种繁多,可根据输送物料和工艺要求选用,能满足各行各业不同的需求;3、机架材质分铝型材、普通碳钢、不锈钢。4、输送能力大,可承载较大的载荷,如用于电动车、摩托车、发电机等行业;板式输送机生产 链板式输送机图片制造厂家5、输送速度准确稳定,能的同步输送;板式输送机生产 链板式输送机图片制造厂家链板式运输机,装配链板输送机6、链板输送机一般都可以直接用水冲洗或直接浸泡在水中,设备清洁方便,能满足食品、饮料行业对卫生的要求;和洗涤用品,使输送链板始终运行在导轨里面,注意勿使绳索损伤带边,设备结构简单7、设备布局灵活。可以在一条输送线上完成水平、倾斜和转弯输送;8、设备结构简单,维护方便。选择方法可根据需要选用相应材质和宽度的链板 。1.参照输送产品-平板链来选型板式输送机生产 链板式输送机图片制造厂家,链板线厂家2.选用不同形式的平板链,可实现平面输送、平面转弯、下降等各种功能。在使用吊车搬运链板输送机的时候,清洗等设备的单列输送的要求。3.电机可根据需要设置在机架下面或机架上面。加厚铁板式运输机减少内部的损耗,从而产生储存量,输送量要求等4.速度调节可选择变频调速或选用无级变速减速电机。板式输送机生产 链板式输送机图片制造厂家,链板爬坡输送机5.输送机可设置侧面挡板,两侧安装控制工位单元,实输送过程的自动化功能。6.根据提供的详细输送物料名称、尺寸和要求机器的材质、尺寸、速度、输送量要求等日常维护链板生产线设备清洁方便,线体可以直接用水冲洗设备的表面(但需注意动力部分及控制部分则不可用水清洗,以免损坏内部部件,触电,发生意外事故。)要想使设备的使用寿命达到大值,维护与保养才是关键。一般而言,动力部分的马达在使用一年左右就需及时更换机油,以马达处在佳运行状态,减少内部的损耗。平时在链板生产线设备使用完后,要及时关闭电源,一段时间对设备表面进行清洁。设备需要维护时,应该由设备人员进行维护,非相关人员不要进行,以免发生造成不必要的经济损失和事故。设备发生故障时不可盲目检查维修,应让工程人员来进行检查维修。在输送机运转过程中,链板生产线遭受各种不一样性质和体积的裁荷效用,居于极复杂的应力状况下。链板生产线典型的毁坏方式有:工作面层和边缘磨耗;受大块矿岩冲击效用引动击穿、撕裂和脱落;芯体经过短笛和托辊组受反反复复屈曲应力引动疲乏;在背景媒介效用下,引动强度指标减低和老化等等。工作原理链板式输送机 ,由动力装置(电机)、传动轴、滚筒、张紧装置、链轮、链条、轴承、润滑剂、链板等等构成。其中带动物料的输送的主要的两个部分为:链条,利用它的循环往复运动提供牵引动力;金属板,作为输送过程中的承载体。其原理主要是利用固接在牵引链上的一系列链条提供牵引力,用金属板作承载体物料随着水平或者倾斜方向输送。链板式输送机被广泛运用于各行各业之中,电力、冶金、酿酒、化工、医疗、机械制造等等宽广的领域。为满足生产现场的各种需求,我们可以对自动化线中的输送机器进行具体设计,来达到要求和目的。板式输送机生产 链板式输送机图片制造厂家链板生产线,挡板式链板输送机由动力装置(电机),应该由设备人员进行维护因公司皮带机,斗式机,螺旋输送机,管式输送机,气力输送机等输送机械生产的规模化。所有配件自产,量产化。包括槽形托辊.平行托辊.锥形调心托辊.摩擦调心托辊.回程托辊.尼龙托辊.不锈钢托辊.橡胶托辊.铰接托辊.支架支柱.冲承座.密封件.橡胶圈.包胶滚筒.传动滚筒.改向滚筒.电动滚筒.逆止器.连轴器.跑偏开关.拉绳开关.头架尾架.中间架支腿的量产。食品输送带,耐高温输送带。阻燃输送带,pvc 输送带防滑输送带,耐酸、耐碱输送带,聚酯输送带,尼龙输送带流水线的规模生产,特钢螺旋s叶片,板式链条【斗式机,管式输送机,各种刮板输送机】生产线的量产化,斗提冲压畚斗,各类塑料畚斗,管式输送机塑料盘片生产线陆续投产、真正实现了厂家,直接与用户见面,简化缩短了流通过程.一、链板输送机主要特点该机为消化吸收国外先进技术而规划定型 不锈钢链板输送机标准,主要特点有:1.倾角大:用于运送散状废纸可达30O;运送捆状废纸的倾角≤22O。2.易损件少:易损件只要粉末冶金含油轴承 不锈钢链板输送机,且也十分耐磨。3.承载力强:长轴、短轴外用了优异合金钢套。4.用材考究:如轨迹为轻轨 不锈钢链板运送机原料,拉紧设备用螺丝、螺杆为不锈钢材质等。5.光滑方法共同。钢套与轴的相对运动几乎没有,使表里链板寿数大大提高。6.槽底板:采用双圆弧板,与各种链板运送机天壤之别。7.槽底板两头加挡边,使偶尔呈现的少数小块状物料不会从两头漏出。8.槽底板一概运用一次成型的冲压件。链板输送机中的运送速度能够改动吗?链板输送机中的运送速度能够依照生产工艺的请求操作。构件尺度:运送机的构件尺度包含运送带宽度、板条宽度、料斗容积、管道直径和容器巨细等。这些构件尺度都直接影响运送机的运送才能。运送长度和倾角:运送线路长度和倾角巨细直接影响运送机的总阻力和所需求的功率。板链输送机以标准板链为承载面,由马达减速机为动力传动,运行在专用导轨中,根据工艺流程及材质不同,板链输送机分为平板链输送机,爬坡板链输送机,顶板链输送机和塑钢链输送机,广泛应用于食品、罐头饮料、洗涤产品等行业,它可满足贵公司所需的自动输送、分级包装、耐磨、防腐、结构精密、运行平稳。板式链输送机不锈钢输送机地毯清洗机打孔链板输送机板式链输送机不锈钢输送机地毯清洗机打孔链板输送机, 地毯清洗机打孔链板运送带局部损人造棉应用时修补避免呈现扩大;不锈钢网带在呈现跑偏时采纳办法纠正;运送的过程中不能带负荷发动;链板不锈钢运送带的运用,要避免托辊被物料覆盖,避免其形成回转不灵漏料卡于滚筒与不锈钢运送带之间,转动部分的光滑不可以污染了不锈钢网带。 出产线链板运送带职业也在发生着飞速的改变与改革,不锈钢链板运送带更好的习惯不同职业的需求,开始规划的时分要充沛考虑到各方面的需求。依据详细参数规划出的运送线链板才能更好的习惯各职业的。运送线链板运送带需求运送的物料的性质及载重的运送能力,在传递成件物品时成见物品的分量和尺度要知道等等;还需求考虑到该设备运用环境,看看它是在露天、室内、干燥、湿润 、环境温度和空气含尘量巨细等等的哪种环境下运用出产的;链板运送机的卸料方法和卸料设备的构成、受料点数目及方位的问题也是需求考虑的问题;不锈钢网带运送机装置的形式以及相关尺度包括运送线链板运送带的长度、提高高度以及倾角等。 金属排屑链板输送机板式链传送带机床附件输送机金属排屑链板输送机板式链传送带机床附件输送机链板输送机的设备通用化、操作简略、修理起来也对比简单、运转牢靠、拆装也便利。一同也能够和别的的一些排屑设备一同运用,构成各种方式摆放的切削处理系统。链板排屑机具有运送功率高,运送速度挑选规模大、流线外型,美观大方,排屑顺利的特色。我公司从事输送机械设备多年,致力于包装设备、运送设备、整线工程等自动化设备的发与制作。的技术优势与的设备质量深受用户的期待和信任;长期以来,全众公司消化、吸收并掌握世界的加工技术与包装机械的前沿技术;的规划理念及工程实绩,提供给各企业的生产后勤援助。跟着生产功率的不断发展。不锈钢链板输送机不断增加的出现在了工业生产中,在稳步发胀的运送机工业中,大家越来越留意不锈钢链板输送机的工作功率等一系列问题,那么咱们应当挑选什么样的不锈钢链板输送机呢?不锈钢链板输送机能够满意饮料贴标、灌装、清洁等设备的单列运送的请求,相同也能够使单列成为多列并行走缓慢,然后产生储存量,满意杀菌机、储瓶台、冷瓶机的很多供料的请求。我厂生产的不锈钢网带输送机的运送面平整润滑,摩擦力小,物料在运送线之间的过渡平稳,可运送各类玻璃瓶、PET瓶、易拉罐等物料。链板采用不锈钢和工程塑料等原料,可根据需要满意各行各业不一样的需要。强壮的运送能力,可承载较大的载荷。准确稳定的运送速度能确保准确的同步运送。灵敏的设备布局可在一条运送线上完结水平、倾斜和转弯运送。 铸造件输送机重型链板输送机扣板链板输送机小型板式链输送机铸造件输送机重型链板输送机扣板链板输送机小型板式链输送机铸造件运送机:也叫铸造件传送带,运送带,链条运送机,链板运送机,运送传动架子,流水线,自动化运送线,铸造件传料机械。锻件件运送机便是用来运送高温1250度左右高温铸造件,锻压件的。铸造件运送机的长处便是可以运送高温件,不变形,耐高温,耐冲击力,抗砸,链板运送机的运送带采用运送高温铸造件的不锈钢链板,铸造件运送机速度可调,可调规模从0.025米-60米/分钟,运送机高度可调,一般是15公分可调规模,铸造件运送机械我们研发了四种:合页链板运送机,平顶链链板运送机,槽钢隔板链板运送机,多片链条运送机。铸造件链板运送机可以做成水平直输的,提高爬坡的,拐弯的。 定做链板运送机需求客户提供的数据 1,链板运送机长度,宽度,高度,速度 2,运送物件的分量,大小,温度,形状 3,运送带的运转速度,可调规模 4,运送机有附件要求吗? 不锈钢链板输送机链条传动带式输送机板式链输送带传送机1、不锈钢链板制作过程中的高速冲载和多颗落料技术在职业已获得主导地位。中大标准链板或修孔,或钢球挤孔,或二次冲孔,耐高温不锈钢链板报价,后两种都是世界水平。2、不锈钢链板冲孔落料模具的的原料得到了优化,硬质合金化。选用光饰机进行链板抛光去毛刺,耐高温不锈钢链板,使得在装置使用过程中不会去挂檫物品3、销轴高速堵截技术在不断的晋级。为了更快更的拼装不锈钢链板对销轴倒角技术的研讨。4、在套筒的选用加工方面:中大标准尺度的用无缝管,中小标准选用卷制,优法为比勒机和MRP预弯法,重要链条套筒也可用冷挤压办法制作。产品主要特点:不锈钢链板现在已经逐步得到了广泛的应用,对于该链板的性能,大家应该都不陌生了,不过在应用过程中一些用户向我们反映不锈钢链板表面会有一些锈斑,这时我们应该如何有效去除锈斑呢,接下来为大家详细说明下:去除不锈钢链板表面的锈斑,可以使用酸洗膏,能够提高不锈钢链板表面的光洁度,在其表面形成一层致密完整,耐高温不锈钢链板批发,附着力强的钝化膜,可以有效延长不锈钢链板的使用寿命,还适用于化工机械、食品机械、印染机械、制药机械、压力容器制造及干燥设备、化工设备及化工设备安装等行业使用、工程构件等表面处理。 新型链板输送机机械板链输送线重工板式链传送带不锈钢链板的产业链已广泛应用在钢铁行业,而它运行过程中呈现的情况一直是咱们的技术人员头疼的问题,其中为常见的就是冲突问题。为此,公司也做了不少的研讨工作。今日,小编与我们分享一下对于不锈钢链板运行过程中的冲突问题的解决方法。近,又一次的探讨和研讨后,公司技术人员为了下降不锈钢链之间的冲突和磨损的冲突,削减冲突阻力减摩资料采用了多种润滑资料。润滑油,油脂,固体润滑剂。在变速器润滑剂链的选择时,首先要考虑的形式,合适的环境温度,润滑链规范。润滑油在运用不锈钢链可以用gb443 64机械油,链浸透防锈润滑油在工厂中,为了避免滴油保管运输损耗,常参加润滑油的增稠剂,一般每个厂家都自调制,作者用了一个退让方案了其防锈润滑功能。不锈钢链板是我们十分熟悉的修建钢材,那么什么使不锈钢链板具有较强的防腐功能呢?据研讨不锈钢链板的抗腐蚀性取决于上面所说的耐氧化的金属铬,可是,铬含量更高时,虽然仍可提高其耐腐蚀的功能,但并不是很明显。原因是用铬对钢进行合金化的处理时,把其外表氧化物的类型改变成了相当于纯铬金属上形成的外表氧化物。这种紧密粘附的富铬氧化物保护外表,避免进一步地氧化。重型链板输送机汽车配件组装生产线板式链输送带 链板输送机分为:重型链板输送机有时也称为隔板运送机,它通常作为地上物流运送设备。重型链板机适用于、摩托车、家电(电视机、洗衣机、电冰箱等)、大型电器、机电等作业。重型板链运送机通常可与悬挂运送机、滚筒运送机、机等构成立体自动化出产线,充分运用各自的长处,以抵达前进出产功率,下降劳动本钱,产品质量的成效,是现代大型企业整厂自动化出产好的组合办法。轻型板链运送机也称为顶板链运送机或平顶链运送机。轻型板链运送机广泛适用于食物、饮料、电子、电器及轻工作业。轻型板链运送机具有十分活络的运送办法,它能充分有效地运用空间,既可规划成各种机型独自运用,又能十分便当地和别的运送设备配套。轻型链板运送机主要特征:构造轻盈、工作平稳、噪音低、保护便当。 重型链板机运送链板资料有:不锈钢、碳钢、铝合金。机架资料通常用碳钢资料。现在,中国自立立异研制的链板输送机,在国际化开展日趋成熟的大布景下,市场规模不断拓展,并逐渐向海外进军,开端向东南亚、非洲、拉美等领域延伸。但是,现阶段正值中国经济社会开展的首要战略机会期,工业作为能源消耗及环境污染的首要领域,在加速建造资源节约型和环境友好型系统的束缚下,面对转型晋级的战略性开展机会,链板输送机亦是如此,开端向清洗化、低耗能化、化、大型化开展。 不锈钢链板冲孔耐高温输送带食品输送机流水线烘干链板厂家板式链1.烘干链板在机械、运输等行业中的作用链板输送机在实际运用上能够完成饮料贴标、灌装、清洗等设备的单列输送的要求,并且可以使单列变成多列并,这样一来就能够满足杀菌机、储瓶台、冷瓶机的大量供料的要求,我们一般把两条链板输送机的头相接组成混合链,这样就能使得输送物品处于动态过度状态,避免了输送线上的瓶子滞留问题,达到空瓶及实瓶的无压力输送。德州链板厂家加工烘干链板2.不锈钢链板冲孔特点说明1)输送能力大,承载物品质量比较大,能够满足很多电车和食品等行业的输送需要2)输送的度达到一种很高的境界,对于精密物品的输送很适合 3)冲孔链板的清洁工作比较简洁方便,很轻松的实现食品、饮料行业对卫生的要求。 4)灵活性比较好。在一条输送线上能够同时完成水平、倾斜和转弯输送的高难度活动。 【链板输送机说明】 链板输送机/网链输送机/链板输送线/链板流水线广泛适于用于食品、罐头、药品、饮料、和洗涤用品、纸制品、调味品、乳业及烟草等的自动输送、分配、和后道包装的连线输送。链板式输送机可以满足饮料贴标、灌装、清洗等设备的单列输送的要求,满足杀菌机、储瓶台、冷瓶机的大量供料的要求,可将两条链板输送机的头尾部做成重叠式的混合链,使得瓶(罐)体处于动态过度状态,使输送线上不滞留瓶子,可以满足空瓶及实瓶的压力和无压力输送。 ·规格:1.直输链板宽度有63.5、82.5、101.6、114.3、152.4、190.5、254、304.8; ·· 2.转弯链板宽度有82.5、114.3、152.4、190.5、304.8。 ·材质:碳钢、不锈钢、塑钢,根据产品的需要可选取不同宽度、不同形状的链板来完成平面输送、平面转弯、、下降等要求。主要特点:1、链板输送机/链板输送线/链板流水线的输送面平坦光滑,摩擦力小,物料在输送线之间的过渡平稳。2、链板有不锈钢和工程塑料等材质,规格品种繁多,可根据输送物料和工艺要求选用,能满足各行各业不同的需求。 3、输送速度准确稳定,能保证的同步输送。 4、链板输送机/链板输送线/链板流水线一般都可以直接用水冲洗或直接浸泡在水中。设备清洁方便,能满足食品、饮料行业对卫生的要求。 5、设备布局灵活。可以在一条输送线上完成水平、倾斜和转弯输送。 6、设备结构简单,维护方便。 The chain plate conveyor takes the standard chain plate as the bearing surface and is driven by the motor reducer; We can make the chain plate conveyor very wide and form a differential speed through the parallel operation of multiple chain plates, and use the speed difference of multiple chain plates to change the multi row conveyor into a single row conveyor without extrusion, so as to meet the requirements of single row transportation of beverage labeling, filling, cleaning and other equipment. We can make the head and tail of the two chain plate conveyors into overlapping hybrid chains to make bottles (cans) The body is in a dynamic transition state, so that there is no material left on the conveying line, which can meet the pressure and non pressure conveying of empty bottles and solid bottles. summary. Chain plate specification of chain plate conveyor: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. characteristic. 1. The conveying surface of the chain plate conveyor is flat and smooth, the friction is small, and the transition of materials between the conveying lines is stable. It can transport all kinds of glass bottles, PET bottles, cans and other materials, as well as all kinds of bags; 2. The chain plate has a wide variety of materials and specifications such as stainless steel and engineering plastics, which can be selected according to the conveying materials and process requirements, and can meet the different needs of all walks of life; 3. The frame material is divided into aluminum profile, ordinary carbon steel and stainless steel. 4. Large conveying capacity and can carry large loads, such as electric vehicles, motorcycles, generators and other industries; 5. The conveying speed is accurate and stable, which can ensure accurate synchronous conveying; 6. Generally, the chain plate conveyor can be directly washed with water or soaked in water. The equipment is clean and convenient, and can meet the hygienic requirements of the food and beverage industry; 7. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line; 8. The equipment has simple structure and convenient maintenance. Application Application: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. It is widely used for automatic transportation, distribution and connecting transportation of subsequent packaging of food, cans, drugs, beverages, cosmetics and washing products, paper products, condiments, dairy and tobacco. There are three kinds of conveyor chain plates: POM material, stainless steel and stainless iron. There are two kinds of turning forms: Wing turning and magnetic turning. The π type turning chain plate is used as the conveying carrier for the turning chain plate conveyor, and the chain plate runs in the special turning guide rail made of high molecular polyformaldehyde; Or use stainless steel turning chain plate and magnetic turning guide rail to make the conveying chain plate always run in the special guide rail, which has the characteristics of stable operation and convenient installation; Classification Chain conveyors are mainly divided into four categories: chain plate conveyor, hanging chain conveyor, mesh belt conveyor and plug-in line conveyor. Equipment introduction The chain plate conveyor can meet the requirements of single row transportation of beverage labeling, filling, cleaning and other equipment. It can also turn a single row into multiple rows and walk slowly, so as to generate storage capacity and meet the requirements of large amount of feeding of sterilizer, bottle storage table and bottle cooler. We can make the head and tail of the two chain plate conveyors into overlapping mixing chains to make bottles (cans) The body is in a dynamic transition state, so that there are no bottles on the conveying line, which can meet the pressure and non pressure conveying of empty bottles and solid bottles. Chain plate material: carbon steel, stainless steel and thermoplastic chain. According to the needs of your products, chain plates with different widths and shapes can be selected to meet the requirements of plane transportation, plane turning, lifting and lowering. Chain plate specification: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. Hanging chain conveyor Suspension chain is a three-dimensional closed-loop continuous conveying system, which is suitable for the automatic conveying of finished goods within and between workshops. According to the method of conveying objects, it can be divided into general and light traction suspension conveying, general stacking type and light stacking type push suspension conveying. The suspension chain adopts ball bearing as the chain running wheel, and the guide rails are made of 16Mn material through deep processing, with a service life of more than 5 years. The chain pitch commonly used is 150 / 200 / 240 / 250, and the single point load-bearing is also different. At the same time, the single point load-bearing of the chain can be increased by selecting the type of spreader. The conveyor line can turn and climb at will, and can adapt to various geographical environment conditions. The transmission line is mainly used for the air distribution of materials in the workshop. A reasonable scheme can organically combine the warehouse, assembly line and other relevant nodes, straighten out the logistics of the workshop to the greatest extent and produce greater benefits. The conveying line can also be used as part of motorcycle frame and drying conveying equipment of spraying equipment. Precautions for use of chain conveyor In the beverage industry, the chain plate conveyor not only saves people time, but also brings convenience. A small conveying process not only meets the requirements of beverage labeling, filling and cleaning, but also plays the role of sterilization and storage. However, when the chain plate conveyor is used, some places need the attention of the staff, as follows: 1. The chain plate conveyor is transported and stored during transportation During transportation and storage, pay attention not to contact with acid-base, oil, water and other pollutants, and keep away from heat source; Avoid long-term direct sunlight and rain and snow; The storage temperature shall be maintained at – 100c-400c and the relative humidity shall be maintained at 50% - 80%. Do not squeeze or collide during transportation and storage. 2. Hoisting of chain plate conveyor When using a crane to carry the chain conveyor, it is best to use rope and steel rod lifting. Firstly, put a steel rod through the hole with mandrel, and hang the rope with stay rod at both ends of the steel rod. When lifting, pay attention not to damage the belt edge with the rope. A fabric rope with sufficient strength can also be lifted through the mandrel hole without steel rod and stay rod. However, an object shall be padded at the place where the rope contacts the belt to prevent the rope from damaging the belt edge. Do not insert the spreader into the coil for lifting, and do not wind the rope around the coil for lifting, so as to prevent the coil from slipping to one side. A forklift with sufficient bearing capacity can also be used for lifting, but the outer ring of the belt shall not be damaged. Daily maintenance of chain conveyor The equipment of the chain plate production line is easy to clean, and the line body can directly wash the surface of the equipment with water (but it should be noted that the power part and control part can not be cleaned with water to avoid damaging internal parts, electric shock and accidents). Maintenance and maintenance is the key to maximize the service life of the equipment. Generally speaking, the engine oil of the motor of the power part needs to be changed in time after it has been used for about one year, so as to ensure that the motor is in the best running state and reduce internal loss. Usually, after the chain plate production line equipment is used, the power supply shall be turned off in time and the equipment surface shall be cleaned for a period of time. When the equipment needs maintenance, it should be maintained by professional equipment personnel, not by non relevant personnel, so as to avoid unnecessary economic losses and safety accidents. In case of equipment failure, do not blindly check and repair, but let professional engineers check and repair. During the operation of the conveyor, the chain plate production line suffers from various load cutting effects with different properties and volumes, living in extremely complex stress conditions. The most typical destruction modes of chain plate production line are: working surface course and edge wear; Breakdown, tearing and falling off caused by the impact of large ore and rock; The core is fatigued by repeated buckling stress after passing through the piccolo and idler group; Under the background media utility, the index of actuation strength decreases and ages. Chain plate conveyor: also known as chain plate conveyor, chain plate line. The utility model relates to a conveying mechanical equipment which uses a circular chain as the traction power and a metal plate as the conveying bearing body. There are two kinds of chain plate conveyors in the domestic market. One is the conveyor made of chain plate composed of chain, supporting shaft and metal plate; One is a chain plate conveyor made of metal plate conveyor belt composed of chain with bending plate and metal plate. Chain plate conveyor is applied to the transportation of heavy parts, and is often used for the assembly of all kinds of motorcycles, automobile assembly conveyor lines and welding conveyors, all kinds of brakes, engine chain plate conveyor, starter chain plate machine, magnetoelectric door chain plate conveyor, generator chain plate conveyor, electric welding machine chain plate conveyor, etc. The conveyor is an indispensable equipment for the whole motorcycle chain conveyor manufacturer. Through assembly line operation, the assembly process of the factory is effectively adjusted and each process is reasonably distributed; In addition, special machines for on-line detection and automatic assembly can be added on the conveyor at will to implement effective product quality control and equipment operation status monitoring, so as to provide necessary guarantee for modern mass production. The conveyor adopts the large pitch needle roller bending chain as the conveying medium, drives the metal panel for circular operation, and the speed of the chain plate conveying line is adjustable. There are standard configurations such as lighting, fan and tooling board. The length of the thread body is selected according to the output. The chain plate conveyor line is a kind of conveying and assembly equipment which takes the large pitch special bending chain as the transmission medium and drives the metal / plastic panel to run circularly. Because the line structure and conveying medium are relatively solid, it is generally used in the conveying and assembly site of heavy goods, and the maximum load per meter can reach 500kg. The conveying speed of the line body is adjustable, including electromagnetic speed regulation, frequency conversion speed regulation, mechanical speed regulation and other speed regulation modes. Generally, the fastest speed is within 15m / min. Due to the needs of working environment and production process, the line can also be made into 90 degree or 180 degree turning type, which can be used for vacuum pumping and detection of air conditioning chain conveyor, refrigerator chain conveyor, electric tool chain conveyor, etc. Various tooling fixtures can be set on the panel to meet the clamping, rotation, assembly and detection of workpieces. Where the surface of the workpiece needs to be protected, the panel can be made of plastic or pasted on the surface of the metal panel. The main structure of the line body mainly includes steel frame structure and aluminum profile structure. The pitch of the conveyor chain can be selected from 38.1mm to 200mm. It is the most ideal equipment for the transportation and assembly of heavy goods. The chain plate conveyor uses a series of chain plates fixedly connected to the traction chain to transport materials in the horizontal or inclined direction. A single steel plate is hinged into a ring belt as the traction and bearing component of the conveyor. The bearing surface is provided with a transverse spacer placed in the tank to drive the ring belt to scrape and transport the coal through the spacer. The utility model is composed of a driving mechanism, a tensioning device, a traction chain, a lath, a driving and reversing sprocket, a frame, etc. It has been widely used in metallurgy, coal, chemical industry, electric power, machinery manufacturing and other industrial sectors of the national economy. characteristic. 1. Wide range of application. Except for materials with high viscosity, general solid materials and finished products can be transported by it; 2. Large conveying capacity; 3. The traction chain has high strength and can be used for long-distance transportation; 4. The layout of transmission lines is flexible. Compared with the mesh belt conveyor, the chain plate conveyor can be transported under the condition of larger inclination angle and smaller bending radius, so the layout is more flexible. The inclination angle of chain plate conveyor can reach 30 ° - 35 °, and the bending radius is generally about 5-8m; 5. In the process of transportation, various processes such as classification, drying, cooling or assembly can be carried out; 6. Stable and reliable operation; Classification 1. The structural types of chain plate conveyor are diverse. Chain conveyor can be generally classified as follows: 2. According to the installation form of conveyor, it can be divided into fixed type and mobile type; 3. According to the layout of the conveyor, it can be divided into horizontal type, horizontal inclined type, inclined horizontal type, horizontal inclined horizontal type, etc; 4. According to the structural type of traction components, they can be divided into sleeve roller chain, stamping chain, casting chain, ring chain and detachable chain; 5. According to the number of traction chains, they can be divided into single chain type and double chain type; 6. According to the structural type of the bottom plate, it can be divided into scale plate (wave type with retaining edge, wave type without retaining edge, deep type with retaining edge, etc.) and flat plate (flat type with retaining edge and flat type without retaining edge, etc.); 7. According to the operation characteristics of the conveyor, it can be divided into continuous type and pulsation type; 8. According to the driving mode, it can be divided into electric mechanical driving type and hydraulic driving type. characteristic. Small floor area and flexible; *The direction is changeable, and the conveying direction can be changed flexibly, up to 180 degrees; *S-type roller conveyor, each unit is composed of 8 rollers. Each unit can be used independently or connected with multiple units, which is convenient for installation; *The S-type roller conveyor can expand and retract freely, and the ratio of the longest and shortest state of a unit can reach 3 times; *S-type roller conveyor can flexibly change the conveying direction, which can be greater than 180 degrees at the maximum. Roller conveyor is applicable to the transportation of various boxes, bags, pallets and other pieces of goods. Bulk materials, small items or irregular items need to be transported on pallets or turnover boxes. It can transport single heavy materials or bear large impact load. Structural form: according to the driving mode, it can be divided into power drum line and unpowered drum line, and according to the layout form, it can be divided into horizontal conveying drum line, inclined conveying drum line and turning drum line. It can also be specially designed according to customer requirements to meet the requirements of various customers. The inner width of standard gauge roller line is 200, 300, 400, 500, 1200mm, etc. Other special specifications can also be adopted according to customer requirements. The standard turning inner radius of the turning drum line is 600, 900, 1200mm, etc. other special specifications can also be adopted according to customer requirements. The drum diameters used for the straight section drum are 38, 50, 60, 76, 89mm, etc. characteristic 1. The conveying surface of the chain plate conveyor is flat and smooth, the friction is small, and the transition of materials between the conveying lines is stable. It can transport all kinds of glass bottles, PET bottles, cans and other materials, as well as all kinds of bags; 2. The chain plate has a wide variety of materials and specifications such as stainless steel and engineering plastics, which can be selected according to the conveying materials and process requirements, and can meet the different needs of all walks of life; 3. The frame material is divided into aluminum profile, ordinary carbon steel and stainless steel. 4. Large conveying capacity and can carry large loads, such as electric vehicles, motorcycles, generators and other industries; Plate conveyor production chain plate conveyor picture manufacturer 5. The conveying speed is accurate and stable, and can be transported synchronously; Plate conveyor production chain plate conveyor picture manufacturer chain plate conveyor, assembly chain plate conveyor 6. Generally, the chain plate conveyor can be directly washed with water or soaked in water. The equipment is clean and convenient, and can meet the hygienic requirements of the food and beverage industry; For cosmetics and washing products, make the conveyor chain plate always run in the guide rail. Pay attention not to damage the belt edge by the rope. The structure of the equipment is simple 7. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line; 8. The equipment has simple structure and convenient maintenance. The selection method can select the chain plate with corresponding material and width as required. 1. Select the plate conveyor according to the conveying product - flat chain, and produce the chain plate conveyor picture, manufacturer and chain plate line manufacturer 2. Different forms of flat chain are selected to realize various functions such as plane conveying, plane turning, lifting and lowering. When using the crane to carry the chain plate conveyor, the requirements for single row conveying of cleaning and other equipment. 3. The motor can be set under or above the rack as required. Thickened iron plate conveyor reduces internal loss, resulting in storage capacity, transportation capacity requirements, etc 4. Variable frequency speed regulation or stepless speed reduction motor can be selected for speed regulation.