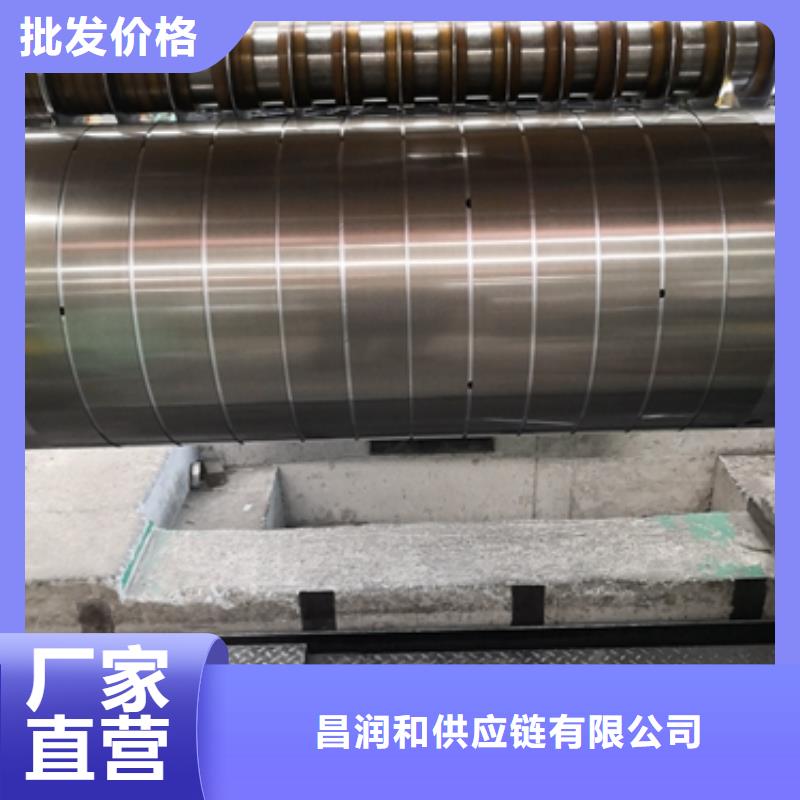

我们为您准备了电工钢硅钢片 B35AH250 0.35*1000【修饰词产品的全新视频介绍,视频中的每一帧,都是产品的真实写照

以下是:电工钢硅钢片 B35AH250 0.35*1000【修饰词的图文介绍

鹿程国际贸易有限公司主营 河南鹤壁汽车大梁钢,为客户提供优质的 河南鹤壁汽车大梁钢产品、良好的技术支持、健全的售后服务以及真诚的态度均得到新老客户的一致好评。公司组织机构健全且拥有一批经验丰富、高素质、率的员工队伍,鹿程国际贸易有限公司是河南鹤壁 河南鹤壁汽车大梁钢企业,如果您对我公司的 河南鹤壁汽车大梁钢产品服务有兴趣,请在线留言或者来电咨询。

电工钢硅钢片本文件规定了公称厚度为 0.18mm、河南鹤壁本地0.20mm、河南鹤壁本地0.23mm、河南鹤壁本地0.27mm、河南鹤壁本地0.30mm 和 0.35mm 全工艺冷轧取向电工钢带的定义、河南鹤壁本地分类和代号、河南鹤壁本地尺寸、河南鹤壁本地外形、河南鹤壁本地重量、河南鹤壁本地磁性能、河南鹤壁本地检验和试验、河南鹤壁本地包装、河南鹤壁本地标志及质量证明书等要求。本文件适用于宝山钢铁股份有限公司生产的以终退火状态交货的全工艺冷轧取向电工钢带(以下简称产品)。2 规范性引用文件下列文件中的内容通过文中的规范性引用而构成本文件必不可少的条款。其中,注日期的引用文件,仅该日期对应的版本适用于本文件;不注日期的引用文件,其 版本(包括所有的修改单)适用于本文件。GB/T 228.1 金属材料拉伸试验 部分:室温实验法GB/T 247 钢板和钢带包装、河南鹤壁本地标志及质量证明书的一般规定GB/T 2521.2 全工艺冷轧电工钢 第 2 部分:晶粒取向钢带(片)GB/T 2522 电工钢片(带)表面绝缘电阻、河南鹤壁本地涂层附着性测试方法GB/T 2900.60 电工术语 电磁学GB/T 3655 用爱泼斯坦方圈测量电工钢片(带)磁性能的方法GB/T 4340.1 金属材料维氏硬度试验 部分:试验方法GB/T 8170 数值修约规则与极限数值的表示和判定GB/T 9637 电工术语磁性 材料与元件GB/T 13789 用单片测试仪测量电工钢片(带)磁性能测量方法GB/T 17505 钢及钢产品 交货一般技术要求GB/T 18253 钢及钢产品检验文件的类型GB/T 19289 电工钢片(带)的密度、河南鹤壁本地电阻率和叠装系数的测量方法YB/T 4292 电工钢带(片)几何特性测试方法Q/BQB 400 冷轧产品的包装、河南鹤壁本地标志及检验文件IEC 60404-8-7Magnetic materialsSpecifications for individual materials – Cold-rolled grain-orientedelectrical steel strip and sheet delivered in the fully-processed stateIEC/TR 62581-2010 Methods of measurement of the magnetostriction characteristics by meansof single sheet and Epstein test specimens3 术语和定义GB/T 2521.2、河南鹤壁本地GB/T 2900.60、河南鹤壁本地GB/T 9637 和 YB/T 4292 界定的以及下列术语适用于本文件。

电工钢硅钢片硅钢是一种硅铁合金。用硅钢轧制的片材是电工领域中应用广的软磁材料,因而硅钢片又称电工钢片。硅钢片广泛用于电动机、发电机、变压器、扼流圈、电磁机构、继电器及测量仪表中电机工业大量使用厚度为0.35~0.50mm的硅钢片,用于:中型旋转机,压缩电机,通用马达,小型精密电机,电动汽车,压缩机,通用电机,电源变压器,精密变压器,节能电机,焊机变压器,稳压器,磁性密封器,加速器用电磁铁,汽车电机等;在电信高频技术中常用0.05~0.20mm的薄带钢片,以便更有效地降低涡流损耗。热轧硅钢片厚度为0.35~0.50mm,密度为7.55~7.70g/cm3,多用于大、中、小型交、直流电动机;冷轧无取向硅钢片厚度为0.35~0.50mm,密度为7.65~7.75g/cm3,多用于大型交流发电机、电动机,大、中、小型交、直流电动机;冷轧取向硅钢片厚度为0.23mm 0.27mm 0.3mm 0.35mm,密度为7.65g/cm3,多用于电力变压器、油浸式变压器,干式变压器,电抗器、磁放大器等;冷轧取向薄带厚度为0.05~0.20mm,多用于无线电高频变压器。

电工钢硅钢片Electrical steel, also known as silicon steel sheet, is an indispensable metal material in the power, electronics, and military industries, and is also the largest functional material in production. It is mainly used as the iron core for various motors, generators, and transformers. Specific total loss (iron loss) is the total power consumed per unit mass of material when the magnetic polarization waveform remains sinusoidal, with a specific peak and frequency. The specific total loss is represented by the symbol P (Jm/f), in W/kg. Example: P1.5/50 represents the specific total loss at a maximum magnetic polarization intensity of 1.5T and a frequency of 50Hz. 3.2 Magnetic Polarization Q/BQB 480-20212 Magnetic polarization intensity refers to the peak magnetic polarization intensity of a specific magnetic field intensity when a sample is subjected to alternating magnetization. Its symbol is J (H), and the unit is T (Tesla). Example: J5000 represents the peak magnetic polarization intensity corresponding to a magnetic field intensity peak of 5000A/m. The material grades in this document are classified based on the nominal maximum specific total loss P1.5/50 (W/kg) at a magnetic polarization strength of 1.5T and a frequency of 50Hz, as well as the nominal thickness of the material. They are further divided into three categories based on product characteristics: ordinary type, stress relief annealing type, and high-efficiency type. Example 1: B35A210 represents a common non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific total loss value P1.5/50 is 2.10W/kg; Example 2: B35AR300 represents a stress relieved annealed non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific total loss value P1.5/50 is 3.00W/kg; Example 3: B35AH230 represents an efficient non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.30W/kg. Example 4: 35WW210 represents a normal type WW non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.10W/kg. Example 5: 35WH230 represents an efficient WH non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.30W/kg. The classification and code of insulation coatings shall comply with the provisions of Table 2. Table 2 Classification and Code of Insulation Coatings Type Code Characteristics of Insulation Coatings Semi organic Thin Coating A Improves Punching Performance and Has Good Weldability Semi organic Thick Coating H has Good Punching Performance and High Interlayer Resistance Semi organic Chromium Free Thin Coating K does not contain chromium and has good weldability Semi organic Chromium Free Thick Coating M does not contain chromium and has good insulation performance Semi organic Chromium Free Extreme Thick Coating J does not contain chromium and has excellent insulation performance Semi organic Chromium Free Ultra Thick Coating L does not contain chromium and has extremely high insulation performance Self adhesive Coating